#ITM 2016

Graf shows innovations in clothings, combs & service machines at ITM

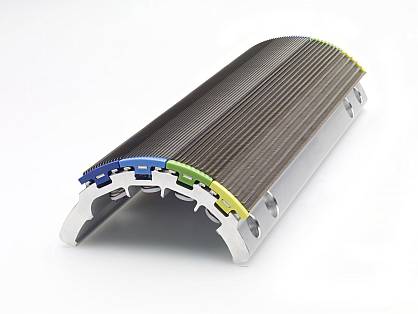

They resist even highest carding forces and guarantee for a high reliability in operation. The EasyTop system can be used for aluminium flat bars with magnetic attachment technology from all manufacturers. EasyTop are available for working widths of 40“, 51” and 60” in a selection of the well-known and proven types of flat clothings.

Graf will also present new products for the combing process. The X-Comb segments can be used on comb-bodies requiring individual segments from other manufacturers and thus now make the leading Graf technology also accessible for these conventional combs. The combing segments made from metallic clothings that undergo a special surface treatment, which substantially reduces the running-in period.

The new circular comb series FlexComb, with height adjustable geometry, a detachable spoiler and a 130° combing surface has been developed for high-performance combers of the latest generation. A short running-in period thanks to the special surface treatment as well as efficient trash removal with optimal fibre selection guarantees cost effectiveness.

In addition Graf will present the DABM flat striping machine for the first time in Istanbul. The DABM allows gentle and correct removal of worn flexible flat clothings from the flat bars. Quick clamping with pneumatic clamping device and the maintenance-free three-phase AC motor without toothed belt are merely two advantages of this service machine. Applicable for flat bars with working widths from 40” – 60”, the DABM allows a Straight-forward and efficient mechanical removal of the worn flat strips from the flat bars.