#Dyeing, Drying, Finishing

GUL AHMED expands production with BRÜCKNER Pad-Dry-Thermosol range

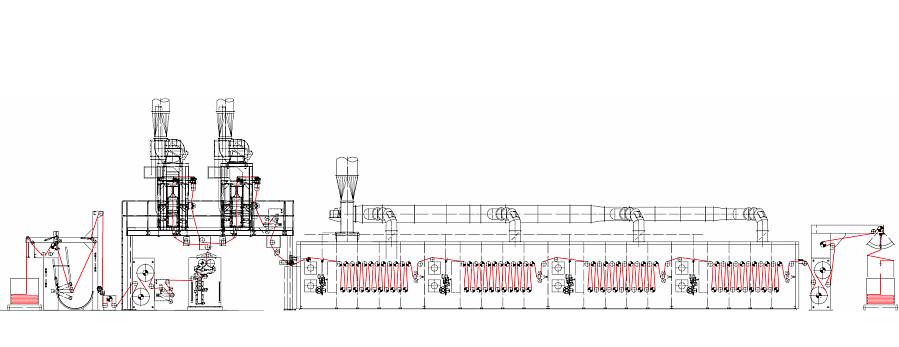

The line consists of one S-Roll padder, two POWER-INFRATHERM pre-dryers and four POWER-COLORTHERM hotflue chambers. The POWER-INFRATHERM dryers represent maximum productivity and flexibility with medium wave length infrared, which is the optimum range for water evaporation. Thanks to trapeze design and staggered arrangement of the perforated stainless steel-fibre panels the formation of stripes is prevented and a perfect overlapping of the radiation over the complete width is guaranteed. A combination of drive adjusting load cells and pendulum compensators assure crease free operation on drying progress.

The BRÜCKNER POWER-COLORTHERM hotflue dryer with four ventilators per chamber stands for an absolutely symmetrical air circulation system which provides unique dyeing results and perfect fabric appearance. Large roller diameter and a sophisticated drive system with individual drives of each second upper and lower roller ensure a low-tension fabric pass. Special designed driven lower spreading rollers facilitate crease free operation of sensitive fabrics such as satin, stripe-satin, weft elastic fabrics and particularly percale even at high production speeds of 70 metres per minute. The new drive system consists of a gear-motor, which is connected via propeller shaft directly to the corresponding guide roller avoiding wear and tear parts as well as sensibility against thermal expansion.

Pic: infrared section (left), entry of hotflue chambers (right)

Mr. Bashir, who was president of the ITMF, is very happy with the performance of the BRÜCKNER thermosol dyeing range. “Mr. Lars Hensen, product manager at BRÜCKNER, trained our technicians on-site and helped a lot to optimize the performance of the line. Now we achieve perfect dyeing results and are able to expand our production for high quality products.”