#Dyeing, Drying, Finishing

Jeanologia joins forces with HKRITA and the H&M Foundation in the new Open Lab in Hong Kong

Located in Hong Kong’s Advanced Manufacturing Centre, this pioneering lab spans 1,800 square meters and is dedicated to the research and development of sustainable textile solutions. It will host over 80 projects focused on sustainability and serve as a meeting point for brands, manufacturers, and suppliers to develop scalable technologies that promote greater circularity and efficiency in the industry. The lab bridges the gap between research-phase innovations and their practical application in textile production.

Jeanologia, aligned with HKRITA’s values, is part of the Open Lab ecosystem, contributing its technology and R&D to advance the Green Machine project. As Enrique Silla, CEO and founder of Jeanologia, explains, “The creation of the Open Lab presents a unique opportunity to unite brands, manufacturers, and suppliers in a collaborative, innovation-driven environment. We are confident that, together with HKRITA and the H&M Foundation, we will make significant strides toward a more circular and efficient textile future."

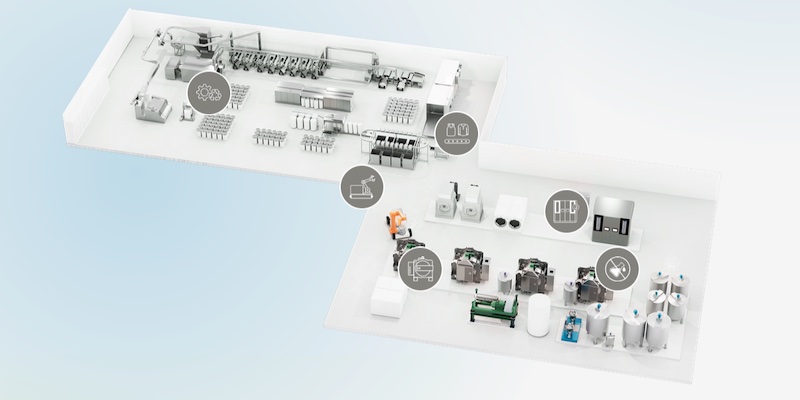

In this cutting-edge space, Jeanologia has introduced some of its most advanced technological solutions aimed at reducing water, chemical, and energy use in the textile industry. Key innovations include the H2 Zero water recovery system, a closed-loop process that allows for the reuse of water without chemicals, while also minimizing energy consumption. The lab also features the eco-efficient Smart Box washing line, which significantly cuts water, energy, and chemical use during textile washing. Additionally, e-Flow technology uses nanobubbles to precisely apply chemicals to garments with minimal water and zero waste. Another highlight is the G2 technology, which uses atmospheric air to generate ozone that interacts with textile dyes to create authentic worn finishes on garments, all without emissions and with substantial savings in water and chemicals.

The new Open Lab, funded by the Innovation and Technology Commission of the Hong Kong government and housed at Hong Kong Polytechnic University, aims to become a global leader in applied research and industrial solutions. At the heart of the facility is the Pilot Plant, an industrial-scale recycling line designed for demonstrations and technology testing. It also features the Green Machine 2.0, which separates polyester fibers from PET-cotton blended textiles at scale, with the capacity to recycle up to one ton of material daily.

The Open Lab is expected to be fully operational by the end of 2024, cementing its status as one of the world’s most advanced centers for sustainable textile technology R&D.

Globally recognized for its disruptive innovations, Jeanologia reaffirms its leadership in transforming the textile industry with its involvement in this ambitious project. The Spanish company emphasizes its collaborative approach to addressing the pressing sustainability challenges the sector faces. “We firmly believe that the future of fashion will be eco-efficient, and through partnerships like this one, we are building that future today," says Enrique Silla, adding that "technological innovation is key to solving the industry’s most urgent challenges."