#Weaving

Automated solutions for quality satisfaction

USTER® fabric inspection systems also reduce waste and improve yield

USTER’s Think Quality approach now takes in automatic fabric inspection, bringing much-needed precision and security to demanding technical textiles applications – and to all weaving mills where quality matters. Quality standards everywhere are increasing all the time: in sectors such as the automotive industry, zero-defect levels are already mandatory. Applications such as airbags, headliners, upholstery and tire cords require flawless quality, continuously. But there are also many other textile industry segments which must fulfill the expectations of demanding customers. In today’s production environments, automated quality solutions are essential.

Automation: for trust and profitability

USTER offers two systems, ensuring that fabrics meet the quality standards required to protect fabric makers and finishers from costly claims and damaged reputations.

Both systems also add valuable extra benefits. The USTER® Q-BAR 2 fabric quality monitoring system prevents waste, while the USTER® EVS FABRIQ VISION fabric quality assurance system significantly improves first-quality yield for all applications. USTER® Q-BAR 2 and USTER® EVS FABRIQ VISION make a real impact on the business success of users – a fact confirmed in numerous installations worldwide. Across a range of different applications and businesses, these users share a common verdict: automated solutions for fabric inspection have earned their trust.

Quality and minimum waste

USTER® Q-BAR 2 is attracting attention through its elegant and slim design, developed for simple installation on existing weaving machines. It represents the latest generation of on-loom monitoring and inspection systems, offering operational improvements for weavers. Positioned directly above the reed on each machine, USTER® Q-BAR 2 is ideally located for earliest detection of fabric defects. This allows the operator to respond quickly to alarms and stop signals. Correcting problems immediately prevents quality issues from continuing, minimizing material waste.

USTER® Q-BAR 2 categorizes and saves fabric faults, creating a ‘defect map’ for each roll, which can be recalled and reviewed later via the intuitive touchscreen. The system offers different classification possibilities and allows rolls to be categorized according to number, size and position of defects, as well as customer criteria. It also grades rolls automatically. In summary, USTER® Q-BAR 2 reduces the need for post-weaving inspection for most applications.

Quality and maximum fabric yield

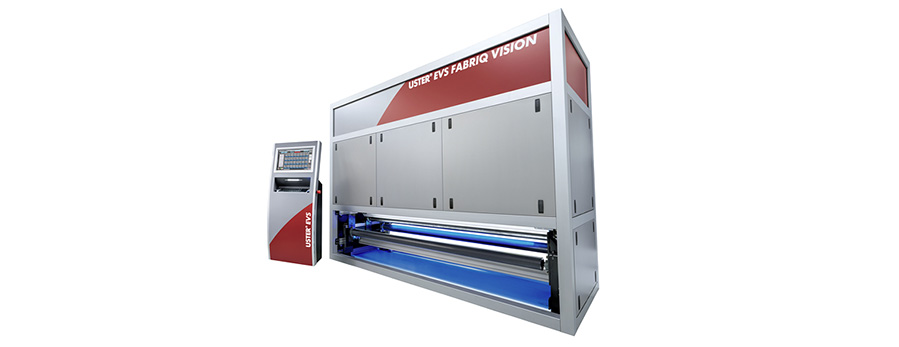

Fabric producers require a consistently high rate of defect detection and optimized efficiency in grading. USTER® EVS FABRIQ VISION achieves this by using automated control during intermediate and final inspection – and by creating roll inspection charts. This removes the need for slow, costly and unreliable manual inspection, freeing operators to focus on higher-skilled jobs. The system’s ability to capture any visible defects allows users to optimize fabric yield.

Best results are achieved by the cut optimization software module of USTER® EVS FABRIQ VISION. This optimizes fabric yield per class, according to the settings. During the inspection process, infrared ink is applied on the fabric. Defect positions are then synchronized with the cut optimization software module. Using the infrared ink marks, the inspection table stops at exactly the right position for each defect, minimizing the risk of errors.

Quality is crucial – and data essential

The increasing demand for assured quality is a significant trend, and achieving it clearly requires automation. A major benefit of automation in fabric inspection is continuity in collecting objective data. This comes with the bonus of automatic data analysis by the USTER® FABRIQ EXPERT quality system, with its fully-customizable reports displayed at the on-screen dashboard. For textile mills, online monitoring of the systems, with comprehensive statistics on inspected fabrics, and machine performance, serves to optimize production and facilitate automation.

USTER® FABRIQ EXPERT provides an overview of all connected USTER® Q-BAR 2 systems in the mill. The main focus is to show quality information – for example the number of defects over a given time – within the relevant context, such as running status or production speed. Technical alarms are highlighted to trigger early reactions, so that problems can be solved as soon as they occur.

Furthermore, smooth interfaces allow users to connect fabric inspection data with existing ERP systems, for true data flow and advanced production automation.

Controlling fabric faults, boosting business

Together, USTER® Q-BAR 2 and USTER® EVS FABRIQ VISION offer effective control over fabric defects and deliveries. “Well-known producers in various industries have already secured their businesses by installing USTER® solutions in their production lines,” says Ingo Kiefer, Product Manager Fabric Inspection at Uster Technologies.

Defects can’t be totally avoided, so it’s vital to locate them precisely. Automated inspection solutions, from weaving up to the end of the production process, allow producers to make correct quality decisions and secure profits.