#Dyeing, Drying, Finishing

Responding to China’s requirements in 2019

In direct response to this situation, A. Monforts Textilmaschinen GmbH & Co. KG has introduced a range of new Industry 4.0 technologies aimed at simplifying machine operation while providing easy access to all data and instant or remote assistance.

At the forthcoming Shanghaitex 2019 textile machinery exhibition, which takes place from November 25-28 in Shanghai, Monforts specialists will be at stand A10 in Hall W and look forward to discussing the company’s latest developments in this area with valued Chinese customers.

They include the latest Qualitex full touch panel control system, with its digital twinning capability and Smart Check and Smart Support apps, reinforced by the comprehensive Monforts Smart Sensor machine monitoring programme.

“On the very latest Monforts machines, our Smart Sensor technologies are controlling selected processing parameter and component, making it possible to access comprehensive technical machine data from any location using the Smart Support and Smart Check apps,” explains Monforts Vice-President Klaus Heinrichs. “The data is virtually mapped in the cloud in real time and provides an instant status overview of a machine’s performance.”

This, he adds, allows for vastly simplified and targeted analysis for both controlled planning and production, and insights harnessed from the data can subsequently be used to further optimise the production process.

“At the same time, potential sources of error can be remotely anticipated and eliminated to considerably minimise downtime while the digital twin capability provides information on the individual wear parts of a system,” says Mr Heinrichs. “As a result, operators can now see how long a part will last and when maintenance or replacement is necessary. Direct access to the integrated Monforts webshop then allows users to order spares at the press of the button whenever they are required.”

This full digital control package is being made available for all Monforts machine ranges and makes operation smarter, and at the same time, considerably simpler.

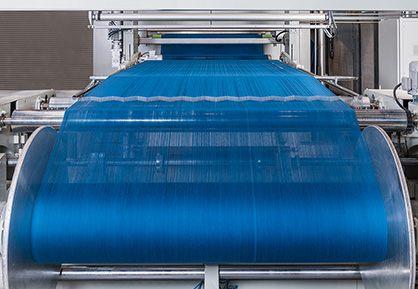

Monforts will also be providing full details of its new CYD continuous yarn dyeing system which is based on the Econtrol® technique – the most effective and established dyeing process for denim fabrics that is now being applied for yarn dyeing. *

Econtrol® is a pad-dry process employed in Monforts continuous dyeing in which the reactive dyestuff is fixed to the cellulose fibres during drying.

The fixing medium is a controlled by a steam/air mixture within the Monforts Thermex unit. With sulphur and reactive dyes in particular, the improvement in both quality and fixation is considerable, and with significant savings in energy and time due to the combined bleaching and padder fixation. The use of the Econtrol T-CA technique also allows the dyeing of cotton/polyester and other yarn blends.?

Weaving preparation

The CYD system also integrates new functions and processes into the weaving preparation processes – spinning, direct beaming, warping and assembly beaming, followed by sizing and dyeing – in order to increase quality, ?exibility, economic viability and productivity.

Further new concepts include the unique Eco Bleach process. This is the first bleaching system for yarn treatment available on the market and is combined with the washing units, after which the fabric is then dyed immediately, resulting in considerable savings in wastewater and chemicals.

It is possible to process short batches of yarn in order to produce minimum runs of finished fabrics in a single continuous process. By comparing the usual processing sequences within the denim industry with the new CYD system, the advantages become immediately clear.

“We are expecting keen interest in our new CYD continuous yarn dyeing system from valued customers in China who did not have the opportunity to visit ITMA 2019,” says Monforts Head of Denim Hans Wroblowski, “especially from the country’s denim manufacturers. We know from the feedback we’ve already received that the CYD system is something the market has been waiting for.”

Trials are currently being carried out with customers on the new CYD yarn dyeing pilot line at the Monforts Advanced Technology Centre in Mönchengladbach, Germany.

* Econtrol is a registered trademark of Dystar Colours Distribution GmbH.