#Digital Printing

Kornit Digital empowers Hybrid Digital to fuel its next stage of business growth

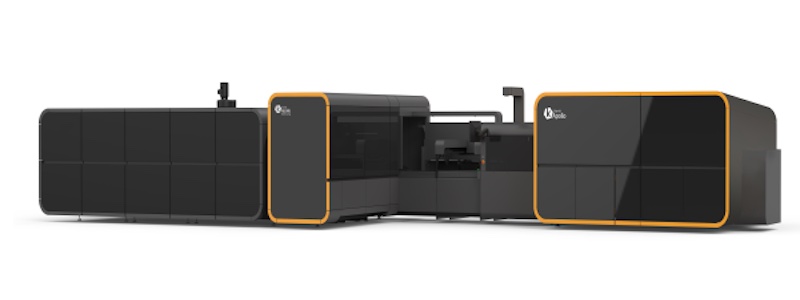

+ Apparel producer servicing major online retailers further drives analog to digital transformation with adoption of the Kornit Apollo automated, direct-to-garment platform

+ Expanded use of Kornit MAX technology solidifies Hybrid Digital’s commitment to high quality digital production, while fulfilling the rapid time-to-market needs of its selling partners

The expanded adoption will further the company’s screen to digital transformation – key to leveraging digital production as its competitive edge and powering new customer expectations for rapid delivery.

Originally a transfer producer and printer, Hybrid Digital made its shift from analog to digital production several years ago to align with emerging production and delivery times demanded by online retail, while ensuring wholesalers can meet requirements for holding little or no wasted inventory. With the Kornit Apollo, Hybrid Digital is responding to the market’s new benchmarks for even faster delivery times – speeding production cycles to serve even more customers faster and fueling business growth.

“At Hybrid Apparel, we are investing in technology and resources to increase our speed to market, improve inventory management, and provide retailers and consumers quality products on demand. With the changing retail landscape and challenges, Hybrid Digital in partnership with Kornit is providing that solution,” said Stephen Teglas, President of Hybrid Digital. “Our track-record of success with Kornit has been incredible, leveraging the technology to capture new market opportunities and grow our customer base during this time of accelerated change. Apollo is one of the most significant steps in digital production we’ve taken in recent years.”

“Changing market dynamics, expectations for accelerated delivery times, and demand for the highest quality garments make digital production more important than ever. Hybrid Digital has built a reputation as a market leader consistently delivering on-demand production for innovative, creative apparel – without being held back by long lead times or lengthy production cycles,” said Ronen Samuel, Chief Executive Officer at Kornit Digital. “Our Apollo system is an industry game-changer, helping customers like Hybrid Digital further embrace all that is possible with on-demand, digital production.”

Ready to learn more about the power of Kornit Apollo? See how the system is helping industry leaders like Hybrid Digital embrace digital production by visiting hybridapparel.com or the Kornit Apollo site.