#Denim

Archroma and Jeanologia launch eco-conscious denim cleaning

(Photo: Archroma)

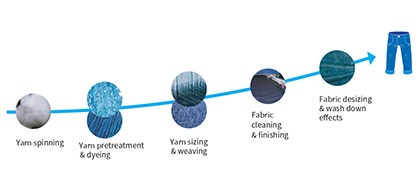

The production of denim requires a succession of several steps aimed at imparting the qualities we love in our favorite pair of jeans.

It all starts with the spinning step where the cotton is turned into yarn. The second step is a pretreatment that will prepare the yarn for the dyeing step. The dyed yarn then goes through the sizing process, which is a treatment preparing it for weaving. At this stage, we have obtained a denim fabric that will go through a few more steps. First, the fabric may undergo a washing treatment or, in some cases, mercerizing treatment which consists of treating it with caustic soda in order to obtain a more lustrous, flat and less reddish blue and black denim.

In both traditional ways to clean the fabric, washing or mercerizing, multiple highly water intensive washings are required in order to restore optimal fabric pH and remove unfixed dyestuff and any undesired deposits or impurities from the fabric. One of such impurities released in the washing process is aniline, a substance that is classified as a category 2 carcinogen and considered toxic to aquatic life.

That is why Archroma and Jeanologia decided to team up and develop an alternative to the traditional fabric cleaning process and its subsequent water-intensive and water-polluting washings.

The breakthrough alternative to the fabric cleaning concept presented by Jeanologia and Archroma combines the use of the aniline-free* PURE INDIGO ICON dyeing system of Archroma, and the water-free** and chemical-free “G2 Dynamic“ finishing technology of Jeanologia.

The Archroma PURE INDIGO ICON is based on an innovation launched by the company in May 2018: its aniline-free* Denisol® Pure Indigo. Aniline is a key ingredient to make the indigo molecule. Unfortunately, during this process some aniline impurities are carried through into the indigo dyestuff. When the indigo is dyed on the fabric, a lot of the aniline impurity is locked into the pigment in the fabric. The remainder of the aniline impurity, approximately 300 metric tons annually, is discharged during dyeing. This can be an issue as aniline is toxic to aquatic life. In addition, exposure levels to factory workers can be high. The new Denisol® Pure Indigo 30 liq was therefore developed as an aniline-free(1) indigo solution for designers, manufacturers and brand owners who long for authentic indigo inspiration.

The Jeanologia G2 Dynamic was introduced in 2008. The market-first ozone treatment for continuous fabric dramatically reduces the amount of water and chemicals used, while at the same time saving costs at the mill and eventually at the garment finishing facilities. This technology makes fabric more stable and consistent and prepares the fabric better for the use of other technologies like laser. As presented a few months ago in partnership with Archroma, this machinery can be used along with Pad-Ox technology to help cleaning fabric thus improving fastness results, at room temperature with significant savings in energy and CO2.

The Archroma/Jeanologia solution allows to create aniline-free* denim, and improve the final aspect of the fabric through a fully chemical-free and almost water-free** cleaning alternative treatment.

The Archroma/Jeanologia solution can also be used with additional Archroma coloration systems such as INDIGO REFLECTION or PURE UNDERTONES.

Umberto Devita, Business Development Manager at Archroma’s Competence Center for Denim & Casual Wear, who was the project leader for this new development, comments: “At Archroma, we strive to develop solutions in line with our principles of “The Archroma Way to a Sustainable World: Safe, efficient, enhanced, it’s our nature”. It was therefore very inspiring to work with a partner who shares the same values of developing efficient new processes to bring all know-how to our customers to maximize value – for denim that looks as good as the good it creates.”

For Jean-Pierre Inchauspe, Business Director of G2 Dynamic at Jeanologia, “this association is another step to change traditional, more polluting and water consuming processes in the textile industry for new ones using technology, improving, and boosting subsequent production stages up to the finishing of the garment, making them more efficient and allowing companies to be more competitive, increase productivity and offer a product that is completely sustainable with high quality.”

For more information about Archroma aniline-free* Denisol® Pure Indigo:

https://www.archroma.com/innovations/the-purest-indigo

For more information about Jeanologia G2-Dynamic technology:

https://www.jeanologia.com/g2-dynamic

For more information about the Archroma/Jeanologia Pad-Ox cold technology:

https://www.archroma.com/press/releases/archroma-and-jeanologia-join-forces-to-launch-pad-ox-g2-cold-a-new-water-saving-dyeing-process-for-denim-and-casual-wear

* Below limits of detection according to industry standard test methods

** Up to 90% water savings