#Denim

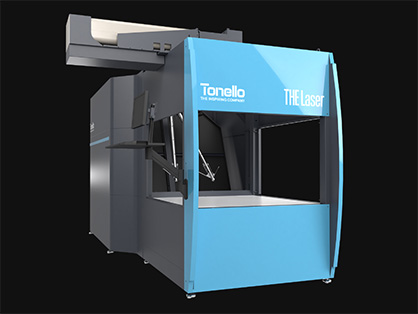

Tonello presents THE Laser, the new innovative, revolutionary laser line

THE Laser, the absolute Laser

A new software, a totally reinvented process. Design and quality finally together, to offer more productivity, flexibility, speed, accuracy, and repeatability. Overall dimensions reduced by as much as a third; possibility of working a continuous cycle, 24 hours a day, 7 days a week; incredible software performance and uncompromising quality: for combining technology and creativity, and pushing them beyond every limit.

These are just a few of THE Laser pluses, presented last Wednesday at the Tonello live-web event.

THE Laser is much more than a new line of machines: it is another (R)evolution signed Tonello, a radical paradigm shift that will result in a better and more efficient way of working.

In other words, Tonello has reinvented the Laser, changed the rules of the game, and nothing will ever be the same again.

THE Laser, the range

Lab, Table, Table & Mannequin, Conveyor: these are the magnificent 4 components of the most complete Laser range ever, to meet all production, creative, and logistic needs.

THE Laser Lab: the most compact, smart, and cool laser in the range. It is characterized not only by its compactness, but also by its easy installation, maintenance, and handling, as well as by the options for it being placed in either shops or in production contexts, depending on the power and, therefore, the speed.

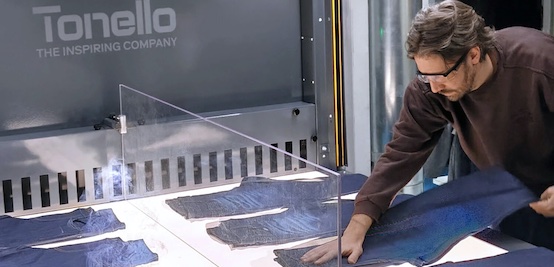

THE Laser Table: is the new Tonello proposal for table work.?Compact in its total volume, but with a larger work area, it is easy to use and allows you to operate either on the entire surface of the table, or alternating processes in two distinct areas. This allows fast, flexible, and alternating production of the garments.

THE Laser Table & Mannequin: radically changes the approach to “table + mannequin” technology. It integrates the innovative features of the Laser Table with the new oblique mannequin, which reduces the overall dimensions of the machine and allows for improved performance of the fully automatic and super-rapid change between the two working modes. The mannequin can also be marked at a full 360 degrees.

THE Laser Conveyor: machine for continuous processing on conveyor belt or traditional fixed table. It allows non-stop laser processing and garment unloading. Ideal for T-shirts and knitwear, it is also particularly flexible for laser cutting jeans.

Co-stars of the range are the absolute latest developments CREA and B.O.P. CREA is a software conceived and developed by designers for designers, smart, intuitive, and user-friendly. Its infinite creative tools allow you to easily modify a design in an instant, directly “on the machine”, and to go directly to production. B.O.P. or Be On Point, is a “one touch” automatic positioning system for design, which does not require particular operator accuracy or precision. This increases the quality and repeatability of marking, while significantly reducing execution times. (Because THE Laser is not only the most complete and innovative range of lasers, it is also the most intelligent, creative and flexible range, already projected towards the future. Otherwise it would not be signed Tonello.)

All of THE Laser’s groundbreaking innovations will be presented for the second time in an exclusive online event, twice on Thursday 26 November: at 9.30am and 5pm (CET). To learn more and participate, click here:

https://us02web.zoom.us/webinar/register/WN_HT0hiI45SSOzFthSFPp9yw