#Denim

Master has changed its core business and presents Bingo

lnterpreting the new demands of the textile market, Master gives life to a new "core business" transferring its exceptional and exclusive know-how, fruit of decades of research and industrial application .of this innovative technology, to the field of fabric dyeing. Hence, Master introduce in this field the possibility to dye in accordance to the most modern concepts of sustainability.

Master enters in this sector introducing a new and revolutionary machine for dyeing, into inert environment, with indigo and other reduction dyes, a several kind of fabric and denim.

With this new machine, which is multipurpose, named "BINGO®" (pat.), in a simply ingenious way, the dyeing of fabrics with indigo and reduction dyes takes a new form: advanced and exclusive technology based on innovation, ecology and economy.

lt is a compact, flexible and versatile machine. lt goes beyond tradition, to open new market opportunities.

Exclusive sustainable technology for sustainable production.

Beyond the tradition, looking to the future, to open new boundaries to the most ancient color. New marketing opportunities in the respect of the most strict eco-friendly concepts for indigo and colored fabrics.

The starting concept

Even good ideas, sometimes, need to be re-interpreted to be adapted to technology and market evolutions. BINGO is exactly the most modern and advanced example of this concept.

Master, strongly supported by his long experience in dyeing machines, has started analyzing today key points of textile market to develop this brand new machine that, recovering some classic production technology concepts, represents a revolutionary solution for fabric dyeing.

The targets Master has pursued while designing Bingo have been:

- Flexibility in processes

- Elasticity in lot lengths from short to long lot

- Absolute reliability of results

- Advanced sustainability.

The ideas:

- Bi-directional fabric movement automatically managed during the complete process

- State of the art engineered solutions to reduce consumptions and costs

- Compact installation - ingeniusly all in one

- High quality together with high flexibility thanks to simple operations

- Low space required / low utilities consumption

- "NIP" to "VIP": "Nitrogen indigo performance" to "Value improved production".

- N2 - our well know developed technology for the modern dyeing with low volume bath.

- Performing chemistry for high dyeing efficiency and high color fastness.

The technology concepts identified as the most suitable to achieve the targets is coming from the “jigger”, one of the most flexible dyeing machine still today largely utilized. In the past Master has already contributed to the development of special jigger versions with the famous “Jumbo” version, realized for M/s Candiani for the dyeing of workwear fabrics with Blue Hydron dyes.

The innovation

Master has strongly worked to re-engineer the jigger concept combining the mentioned advantages with his well experimented dyeing technology in Nitrogen atmosphere.

The result is Bingo: a revolutionary machine, the combination of a strong background with the most innovative and sustainable dyeing process.

Bingo can perform dyeing processes based on indigo and other reduction dyes (Sulphur, VAT, etc.) for denim and other fabrics.

- Drastic reduction of water consumption per meter of fabric.

- Enormous reduction of chemicals uses and

- eco-friendly dyeing recipes.

- No fabric wastages and perfect reproducibility of dyeing results short and long lots.

- Suitable from the lightest to the heaviest weight.

- From light to extra dark colors.

- Pure indigo, sulpuhr, VAT colors, etc.

- No minimum lot length requirements.

- Low running cost, low environmental impact.

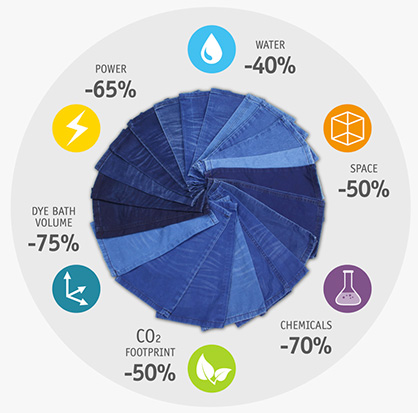

"GREEN" ADVANTAGES

Comparing BINGO with traditional dyeing technology*

Tests were conducted with Denisol® Pure Indigo and Diresul® dyes by Archroma

(*) "indicative values based on standard process"