#Composites

Teijin develops foldable fiber-reinforced plastic structure

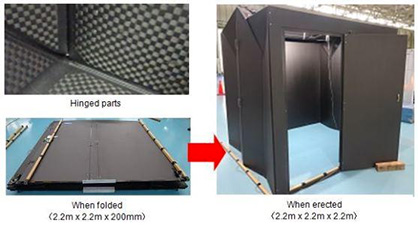

ORIBAKO comprises a polyhedron structure made of FRP panels and hinges that can be easily transported, deployed, folded away and stored. FRP with soft resin is used for the hinges to provide elasticity, flexibility and durability as well as a tight seal. The product can be produced in a variety of shapes and sizes, such as small boxes or simple architectural structures. Using the unique FRP technology that Teijin has developed over the years, the FRPs used for the panels and the hinged sections are integrated seamlessly, ensuring airtightness and a smooth surface with no ridges. Depending on its intended use, the composition of materials used for the panels and hinges of the ORIBAKO can be adjusted to incorporate properties such as sound absorption, heat insulation or shock absorption.

Teijin and GH Craft will unveil a prototype of large ORIBAKO structure at SAMPE Japan (booth A: S-18) which will take place at Pacifico Yokohama from September 4th to 6th. The prototype will comprise a simple booth in which carbon fiber composite panels are bonded to glass fiber composite hinges. It will have a floor area of about 11 square meters and weigh about 40 kilograms. The booth can easily be erected by two adults without the need for tools or machinery.

Teijin and GH Craft will continue to enhance ORIBAKO's properties by expanding the range of materials used in its construction, aiming to make it commercially available by 2022. ORIBAKO is expected to be used in a variety of scenarios, such as a temporary indoor space with external solar panels and as a delivery container allowing easy and rapid change of cargos including those require a tight seal.

In order to meet the ever-diverse needs of society, the two companies will continue to develop their multi-material design and molding processes, leveraging their strengths in high performance materials and composite technologies. In this way the Teijin Group will continue to strive being a company relentlessly focused on supporting the society of the future.