#ITMA-Asia + CITME-2014

VDMA: German Technology combats pollution

At the Aachen-Dresden-Denkendorf International Textile Conference held in Aachen at the end of November, Peter D. Dornier, Chairman of the Walter Reiners Foundation of the VDMA, honoured five successful young engineers. Promotion and sustainability prizes were awarded in the categories bachelor/project theses and diploma/master theses. Academic theses that develop solutions for resource-saving products and technologies, for example, are eligible for the sustainability awards.

With 69 exhibiting member companies, ITMA ASIA + CITME 2025 is once again marked by a strong presence of VDMA companies. Altogether 82 companies from Germany will exhibit at the show, covering about 3,500 square meters of exhibition space, topped only by China and Italy. VDMA initiated a German Pavilion with two group stands (spinning in hall 4 and finishing in hall 7) with a total of 30 exhibitors.

ITMA ASIA + CITME end of October in Singapore will see a strong participation of around 70 VDMA member companies. They will cover nearly all different machinery chapters along the textile value chain including spinning and man-made fibres, nonwovens, weaving, braiding, knitting & warp knitting, finishing & dyeing as well as technologies for textile recycling and processing of recycled material. VDMA initiated a German Pavilion with two group stands (spinning in hall 4 and finishing in hall 7) with a total of 30 exhibitors.

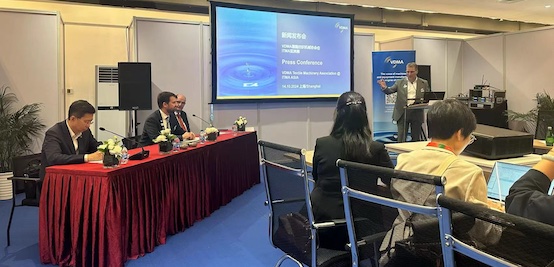

With 42 exhibiting member companies, ITMA ASIA + CITME 2024 is once again marked by a strong presence of VDMA companies. They cover nearly all different machinery chapters with a focus on spinning and man-made fibers, nonwovens, weaving, braiding, knitting & warp knitting, finishing & dyeing as well as technologies for textile recycling and processing of recycled material. In total, the German participation at the fair is the largest from outside China.

Dear reader, the year 2025 is drawing to a close. We are entering what we hope will be a peaceful holiday season, spending time with our families and taking a moment to pause and reflect. We hope we have been able to support you once again this year with relevant news and articles, and we look forward to surprising you with many innovations in the coming year. Enjoy the festive season, stay healthy, and we wish you a happy and joyful holiday season.

After more than ten successful years at Lindauer DORNIER GmbH, Mr Wolfgang Schöffl will leave the family-owned company at the end of the year to enter well-deserved retirement.

Under the banner 'Texpertise Focus AI, Messe Frankfurt will place a strong emphasis on Artificial Intelligence (AI) across its international textile and apparel trade fairs from 2026 onwards, setting a future-shaping signal for the industry. The initiative highlights the responsible use of AI along the entire textile value chain, from fibre production to the point of sale. The programme will launch at Heimtextil in Frankfurt in January 2026.

As the global market leader in sustainable acoustic and thermal management, Autoneum is a key supplier of interior and exterior components for the highly anticipated Polestar 5 model. The successful collaboration between Autoneum and Polestar marks a significant milestone in sustainable automotive engineering: the electric grand tourer sports car features several innovations in lightweight, fully recyclable polyester-based components that ensure a superior driving experience. Polestar 5 was revealed at the IAA Mobility 2025 in Munich and is available in 24 markets.