Weaving

Stäubli Textile demonstrates its innovative force at ITMA Asia / CITME 2014

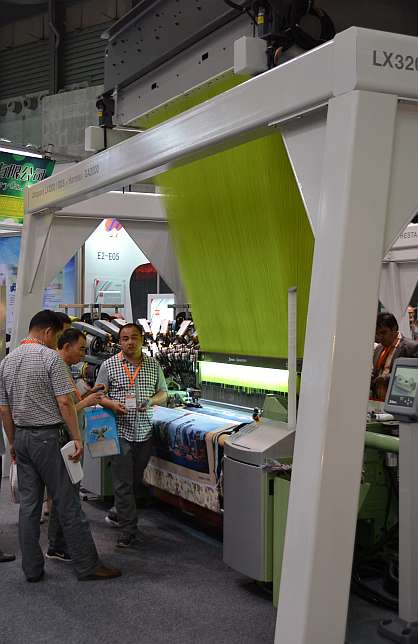

Four weaving machines with Stäubli Jacquard machines produced exclusive fabrics at the booth, and a total of 11 Stäubli Jacquard applications could be seen at other booths at the show. The great popularity of our machines encourages us to continue our innovative research and development.

Applications and solutions with Stäubli frame weaving systems were also presented at the Stäubli booth. No less than 60 Stäubli dobbies and cam motions were in operation on several leading global brands of weaving machines, producing a wide range of products, from standard fabrics to the most difficult technical textiles.

Stäubli Weaving Preparation Systems demonstrated its SAFIR S30 automatic drawing-in system, a most powerful tool that excels in highly productive filament mills. This system has been enthusiastically accepted by Chinese customers and is part of Stäubli’s complete product programme for automation in weaving preparation. Stäubli’s weaving preparation solutions also include warp-tying and warp-leasing systems that deliver significant advantages for users.

In line with its customer benefit strategy, Stäubli showcased a large display of original spare parts in a dedicated area of the booth, emphasizing that the use of original spare parts ensures top performance and assures long service life of the machines. Stäubli spare parts can be ordered online using the interactive spare parts catalogue.

Stäubli Group member Schönherr presented innovative machines that offer new opportunities for every carpet mill. Interest was strong, as the Chinese carpet industry sees great potential in traditional markets. Visitors were intrigued by the new binding technologies that enable creative patterns, like the Magic Weft Effect created using the Multi Weft Selector.

DEIMO, Stäubli Group member and specialist for automation solutions, presented its products and know-how at a separate booth in Knitting Hall 5, close to its prospective OEM customers.

Pic: Jacquard Installation (c) 2014 Stäubli