#Dyeing, Drying, Finishing

Trendsetting technology. Worldwide. And at the K13.

- Process and quality control (sheet & film extrusion, weight, thickness, moisture, etc.)

- Residual moisture control

- Exhaust humidity control

- Pattern and repeat measurement and control.

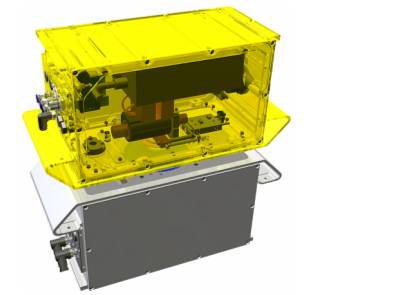

Automation and Web Process Control: Qualiscan QMS-12

Reducing the usage of energy, raw material and human resources while optimizing quality, equipment utilization and work flow, nowadays is a precondition to keep the market position. The perfect tool for that is the Qualiscan QMS-12. The modular-structured system for measurement, control and logging of critical process variables, such as weight per unit area, coating weight, moisture, thickness, etc., covers the full working width of the product.

Non-nuclear weight measurement

The standard in basis weight measurement has always been measurement with beta gauges. In times of rising radiation protection requirements gradually more non-radioactive measurement techniques are establishing. Some new sensors for the Qualiscan QMS from Mahlo are available in that area.

The Gravimat FMX-T is a low voltage X-ray sensor that measures the basis weight (or calculated thickness) of thin films, nonwovens, and other webs with ultra-fine resolution, accuracy and defect detection. The X-Ray energy below 5kv exempt from regulations.

Pic: Gravimat FMX-T: Non-nuclear basis weight measurement

The Infrascope NIR monitors the absorption of infrared energy by components on or in the web in the near infrared region. By simultaneously analyzing the entire NIR Spectrum, the sensor is able to discriminate between multiple components in the web.

The Infrascope NIR-I sensor uses white light interference to measure precisely the layer thickness of mono layers and transparent coatings on film. By a special measuring procedure, both the layer thickness and the film thickness can be determined accurately on-line.