#Dyeing, Drying, Finishing

Ready for summer: Why textile precision matters in swimwear

Elastic, shape-retaining, and chlorine-resistant

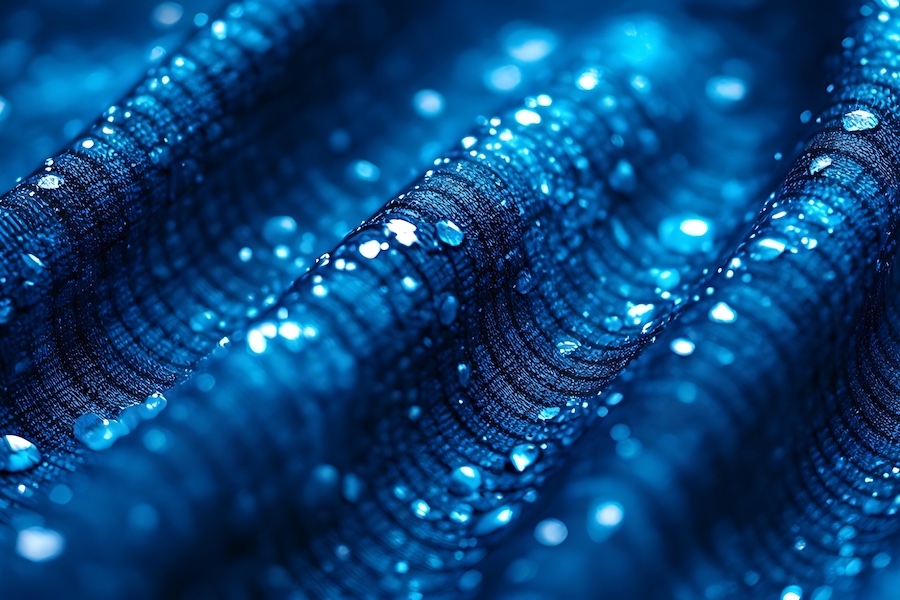

Swimwear must meet a wide range of requirements: high elasticity, recovery, UV resistance, and durability against chlorine are basic standards. These properties are made possible by technical knits based on polyamide or polyester combined with elastane. Typically produced in tricot knit, these fabrics are stretchable in both directions – ideal for a close fit and full freedom of movement in water.

But to achieve a perfect final product, the material composition alone is not enough. Processing in the earlier production stages – especially fabric forming and finishing – plays a crucial role. Elastic materials are particularly prone to distortion. If this isn’t corrected before further processing, the result can be skewed patterns, uneven seams, or misshaped silhouettes.

Distortion-free fabric as a quality feature

This is where Mahlo’s Orthopac RXVMC comes into play. The latest addition to the weft straightener family is designed specifically for elastic materials with high distortion dynamics – a common feature in swimwear.

Equipped with two independently driven straightening modules – one at the fabric’s entry and one at the exit – the system enables particularly fine and rapid corrections. It reliably compensates for skew and bow distortions before the fabric continues to the next production steps. The result is not only improved fit but also stable printing and finishing outcomes.

Technology for perfect finishing

Only when the fabric is precisely aligned can finishes like chlorine resistance, UV protection, or the popular lotus effect be applied evenly. Accurate dosage is critical: too little finish limits functionality; too much wastes raw materials and drives up costs.

To ensure precise control of these processes, Mahlo has developed the Qualiscan QMS – a modular online measurement system equipped with application-specific sensors for thickness, basis weight, or moisture. It continuously monitors the finishing process, ensuring consistently high product quality.

Conclusion: Precision saves your summer

Swimwear may look light and playful at first glance – but in reality, it’s backed by highly sensitive textile technology. Only when all stages – from fabric alignment to straightening and finishing – are perfectly coordinated, can a product emerge that passes the ultimate summer test. With technologies like Orthopac RXVMC and Qualiscan QMS, Mahlo provides the tools to manufacture summer textiles that are not only stylish but also functional and cost-efficient.