#ITMA Asia + CITME 2024

Mahlo reflects on key insights and highlights from ITMA Asia + CITME 2024

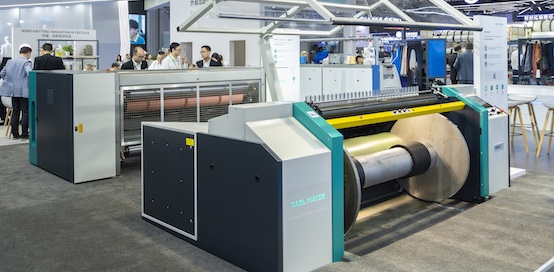

Mahlo showcases advanced weft straightening solutions at ITMA Asia

Mahlo presented innovative weft straightening solutions at ITMA Asia, unveiling the new Orthopac RXVMC-20 and Orthopac RVMC-20 plus models. The RVMC-20 plus, in particular, stands out as a versatile device, installable as a stand-alone system or as an upgrade for the RVMC-15. Mahlo’s engagement with an international audience highlighted the strong demand in Asia, with many visitors from Pakistan, India, Bangladesh, and Indonesia showing interest in high-quality textile solutions.

New Mahlo systems generate strong interest from ITMA Asia visitors

Mahlo's complete range of weft straightening systems, including the Orthopac RXVMC-20 and FMC-15, attracted significant attention for their ability to enhance fabric quality through precision control. The company’s process control systems, such as the VMC-15, PMC-15, and SMT-15, also impressed visitors, offering energy-saving benefits and optimized production efficiency—key priorities for manufacturers in a cost-conscious industry.

Orthopac RVMC-20 plus: a solution tailored for cost-conscious textile manufacturers

The newly launched Orthopac RVMC-20 plus bridges the gap between Mahlo's RVMC-15 and high-performance RXVMC-20. This model meets the specific needs of the knitwear sector, offering advanced weft straightening at a competitive price, balancing affordability with performance for cost-sensitive markets.

Growing demand for precise weft straightening drives innovation at Mahlo

Perfect weft straightening is essential for manufacturers of high-quality textiles and technical fabrics, with demand expected to rise as the industry emphasizes superior alignment and uniformity. Mahlo remains well-equipped to meet these evolving demands, reinforcing its role as an expert in achieving unparalleled weft straightening results.

Customer feedback reinforces Mahlo’s commitment to innovation and quality

Feedback from customers and industry peers at ITMA Asia validated Mahlo’s reputation for advanced and competitive solutions. This recognition strengthens Mahlo’s commitment to developing state-of-the-art systems that align with industry trends and customer expectations, ensuring ongoing innovation in response to market demands.