Yarn & Fiber

Trevira GmbH & Trevira CS: Business, activities, projects

Economic activity in the euro area remains weak, while export business in overseas markets, which has shown a steady rise in recent years, could be further expanded.

The restructuring steps taken over the past years at Trevira have brought about a further improvement in profitability. At both sites there has been considerable investment in optimising processes, infrastructure and in plant. Alongside comprehensive measures in filaments, future projects were set in motion also in the fibres unit, such as an on-site boiler house for the production of process steam and a conversion plant; both projects were officially commissioned in the autumn.

Trevira CS – business with flame retardant products

Despite a difficult economic background and a continuing slow-down in investment, especially in the (south) European contract market, in the 2014 business with flame retardant fibres Trevira succeeded in generating volume growth of 4-5 % over the previous year.

Here growth was achieved both in the traditional textile sector and in technical applications (nonwovens). Nonwovens were also notable in showing a significant volume rise in the spun-dyed segment, which should continue into the coming year. Alongside this there are at present a variety of qualification processes running with North American customers. These promise a solid basis for more growth next year, given a positive conclusion.

Business in flame retardant filaments also made stable progress in 2014, showing a slight rise on the previous year. The many new developments in Trevira CS on the market are cause for an optimistic outlook in the New Year. Particular mention should be made here of the ongoing positive development of textile materials incorporating Trevira low-melt yarns, which are being used in the sun protection and acoustics sectors.

Trevira also sees good future prospects for business in Asia, as higher fire safety standards gain more ground there. These offer potential to supply producers for local use, but also for high-end collections from Europe. Meanwhile Trevira CS is also being used in China, in hotels, the office sector, as well as in public buildings such as theatres.

What sets Trevira CS aside from other FR products is the wide variety of fibre and filament yarn qualities available, together with the provision of services catering for the whole textile chain. The market has seen the introduction of UV stabilised yarns in new products for use in upholstery and decorative fabrics for the outdoor sector (cruise ships, hotels, restaurants etc.). These are currently in the implementation and field test phase at a number of customers. At the yarn level another new development can be seen in Trevira CS filaments on the basis of 100% recycled bottle chips. Forming part of the sustainability concept, they will cover new fields of application.

Based on new polymer modifications, these product developments are set to open sales opportunities not only in the contract sector, but also in technical applications and in the private market.

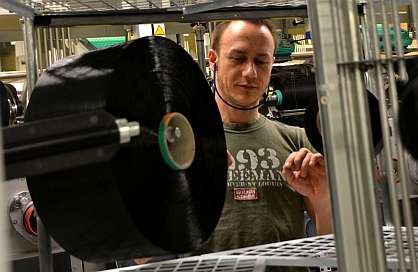

Pic: Trevira Filament yarn production in Guben © Photos: Trevira GmbH