#Yarn & Fiber

The LYCRA Company launches New LYCRA® brand products at Intertextile Shanghai

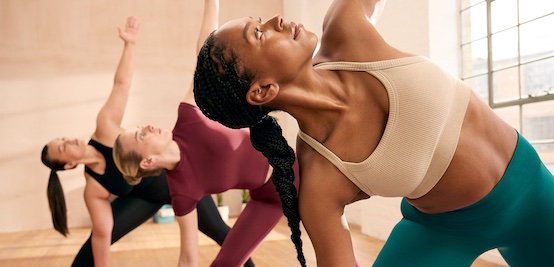

To meet the market’s need for durable apparel offering more inclusive sizing, enhanced comfort and greater functionality, The LYCRA Company is expanding its LYCRA® ADAPTIV fiber portfolio to include two new fibers: LYCRA® ADAPTIV BLACK fiber and LYCRA® ADAPTIV XTRA LIFE fiber.

LYCRA® ADAPTIV BLACK fiber is for long-lasting activewear and athleisure apparel that helps reduce fiber damage caused by UV rays, sunscreen, and anti-chafing creams that can negatively impact a garment’s fit, functionality and lifespan. This technology also provides durable, spun-in true black color that resists fading and minimizes fiber grin-through and glitter. Garment makers and brands can create size-inclusive garments that deliver a second-skin fit and enhanced comfort with this versatile fiber.

LYCRA® ADAPTIV XTRA LIFE fiber is the solution for durable swimwear and activewear that lasts up to 10 times longer than garments made with unprotected spandex, while also providing shaping, dynamic comfort, and a wider fit window to adapt to different body types and enabling easy donning and doffing. The Rosset Group, one of Latin America’s largest and most differentiated knitters, developed the fabrics with LYCRA® ADAPTIV XTRA LIFE fiber for Intertextile.

The LYCRA Company is also launching LYCRA® SHEER SENSATION technology in China. This proprietary anti-static version of LYCRA® fiber was developed in response to consumer insights that indicated sheer hosiery consumers desired a permanent solution to annoying static cling.

The LYCRA® brand booth will also feature fabrics and garments made with LYCRA® FitSense™ technology, moisture-wicking COOLMAX® technology for cooling and THERMOLITE® technology for lightweight warmth.

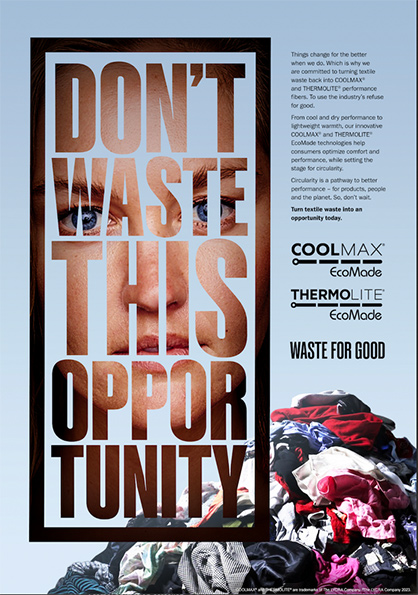

Sustainable solutions on display include our family of fibers made from 100% textile waste, 100% recycled PET, and pre-consumer recycled fiber, which are offered under brands LYCRA® EcoMade, COOLMAX® EcoMade and THERMOLITE® EcoMade. Attendees can also learn about the development of bio-derived LYCRA® fiber made with QIRA®, This sustainable offering made with field corn has the potential to reduce CO2 emissions by up to 44 percent* versus spandex made with traditional raw materials.

Intertextile Shanghai is also the Asia-Pacific launch pad of a new sustainability brand campaign by The LYCRA Company entitled “Waste for Good.” The messaging promotes the advancement of circularity in the apparel and textile industry with COOLMAX® and THERMOLITE® EcoMade technologies.

“We are thrilled that Intertextile Shanghai is back, and we look forward to meeting with strategic partners and new customers in person after its cancellation last year,” said Vincent Hu, vice president, Asia, apparel and president of the APAC region, The LYCRA Company. “We will have two years of new products on display, and we are anticipating great interest in our range of innovative and sustainable offerings designed to meet consumer needs.”

The LYCRA® brand pavilion, located in Hall 4.1, boasts its largest exhibition space yet at 932 square meters and features 28 co-exhibitors united under the theme of “Co-Create the Future Today.” Visit the Intertextile Shanghai event page on lycra.com to learn more about the pavilion, see its floor plan and explore the virtual showrooms of co-exhibitors.

*Estimate from Cradle-to-Gate Screening LCA for a representative LYCRA® fiber manufacturing facility, June 2022, Ramboll US Consulting, Inc.