#Yarn & Fiber

Lenzing reports improved results in the third quarter and remains strategically on course

In addition, Lenzing also intensified measures for structural earnings improvement to mitigate the effect of the pressure on fiber prices and demand for fibers, and reduced its operating costs significantly as a result.

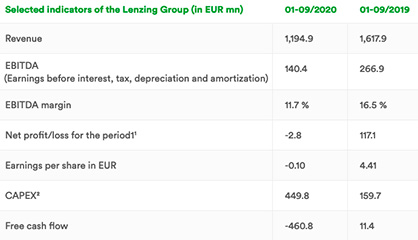

The immediate effects of the COVID-19 crisis increased the pressure on prices and volumes in the textile fiber segment, in particular in the second quarter of 2020. The increase in demand towards the end of the third quarter, primarily for wood-based specialty fibers such as TENCEL™ Modal and LENZING™ ECOVERO™, had a positive impact on the revenue and earnings development, but was still below the level of the previous year. As a result, revenue declined by 26.1 percent to EUR 1.19 bn in the first three quarters of 2020. The earnings development essentially reflects the decline in revenue. The implementation of measures for structural earnings improvements in all regions mitigated this effect. EBITDA (earnings before interest, tax, depreciation and amortization) fell by 47.4 percent to EUR 140.4 mn in the first three quarters of 2020. The EBITDA margin decreased from 16.5 percent to 11.7 percent. Net loss for the period[1] amounted to EUR minus 2.8 mn (01-09/2019: net profit of EUR 117.1 mn) and earnings per share to EUR minus 0.10 (01-09/2019: EUR 4.41).

“Lenzing reacted quickly to the increased pressure on prices and volume caused by the COVID-19 crisis and consequently held its ground in this extremely difficult market environment due to a comprehensive set of measures. In the third quarter, we saw a broad recovery of the fiber market; in particular, demand for our sustainably produced specialty fibers increased significantly”, says Stefan Doboczky, CEO of the Lenzing Group. “Strategically, we remain fully on track despite the pandemic, and the implementation of our key projects in Thailand and Brazil is progressing as planned,” says Doboczky.

Strengthening specialty fiber growth

CAPEX (expenditures for intangible assets and property, plant and equipment and biological assets) roughly tripled to EUR 449.8 mn in the first three quarters of 2020. This increase is a consequence of the progress of the major projects in Brazil and Thailand. The Lenzing Group’s investment activities continued to focus on expanding the internal production of pulp, increasing the share of specialty fibers and implementing the climate targets in line with the sCore TEN corporate strategy during the reporting period.

The construction of the dissolving wood pulp plant in Brazil continues to progress according to plan. After the final investment decision in December 2019, the Duratex Group acquired a 49 percent share in the in the joint venture LD Celulose in the first quarter of 2020 as agreed. Lenzing holds 51 percent of the shares. The expected Industrial CAPEX will be USD 1.38 bn. The project is predominantly financed through long-term debt. The corresponding financing contracts were concluded in the second quarter of 2020 as planned. IFC, a member of the World Bank Group, and IDB Invest, a member of the IDB Group, support the investment program of the joint venture LD Celulose. The export credit agency Finnvera and seven commercial banks are also participating in the financing in the amount of USD approx. 1.1 bn. The commissioning of the pulp plant is scheduled for the first half of 2022.

Specialty fibers are Lenzing’s great strength. The strategic target to generate roughly 50 percent of revenue with specialty fibers in 2020 has already been met. Lenzing aims for further organic growth in this area in order to be even more resilient to volatile markets in the future. The focus of the coming years will clearly be on the construction of the new, state-of-the-art lyocell plant in Thailand, with the objective to increase the share of specialty fibers in the revenue generated by the Segment Fibers to more than 75 percent by 2024. The investment for the new plant with a capacity of 100,000 tons amounts to roughly EUR 400 mn. Construction work started in the second half of 2019 and went according to plan during the reporting period. Production is expected to be launched at the end of 2021.

Sustainability at Lenzing – Stand up! Against business as usual

In its Sustainability Report 2019, which was presented under the title “Stand up! Against Business as usual” in March, the company sets out in detail how it is actively dealing with the global challenges and contributing to mastering the problems caused by climate change. With the implementation of the two key projects in Brazil and Thailand, Lenzing is achieving an important milestone in its carbon neutrality strategy. Both projects are designed as CO2 neutral plants. In addition, the pulp plant in Brazil will be one of the world’s most productive and most efficient plants and feed more than 40 percent of the electricity generated into the public grid as “green energy”. In 2019, Lenzing committed to reducing its greenhouse gas emissions per ton of product by 50 percent by 2030 (baseline: 2017) and to become climate neutral by 2050.

The introduction of the first TENCEL™ branded CarbonNeutral® fibers and the foundation of the Renewable Carbon Initiative with the objective to speed up the transition from fossil carbon to renewable carbon are another two successful examples from the reporting period showing the path Lenzing and its partners are taking towards carbon neutrality.

First direct complete train from Vienna to China

Lenzing is currently testing shifting more freight traffic to rail in order to optimize its own logistics processes with a view to achieving its climate targets, and to further improve the delivery service level. In the third quarter, Lenzing was the first Austrian company to send goods 100 percent “Made in Austria” by train directly to China. Transport by rail is roughly twice as fast as by the usual sea freight, which takes several weeks.

State Prize for Innovation for LENZING™ Web Technology

The award of the Austrian State Prize for Innovation further underlines Lenzing’s achievements and its strategy to grow exclusively on the basis of sustainable innovation. Lenzing convinced the jury with its LENZING™ Web Technology. The novel process is a pioneering achievement and combines fiber and nonwovens production in only one step, setting new standards in terms of efficiency, circularity and ecological sustainability.

Hygiene Austria joint venture: Production of high-quality hygiene and protective equipment

Lenzing proved that it looks beyond fibers and meets the needs of its customers and partners as well as consumers when the company founded Hygiene Austria LP GmbH in the second quarter of 2020 to meet the population’s increased demand for high-quality hygiene and protective equipment. The new company, in which Lenzing holds 50.1 percent and Palmers 49.9 percent, started producing and selling mouth-nose and FFP2 masks from May 2020. In a next step, the product range was extended to include masks for children. Hygiene Austria LP GmbH launched an online shop (www.hygiene-austria.at), thus making another contribution to the security of Austrian supply. Since the third quarter, the high-quality protective masks for children and adults have also been available at Spar, Hofer and the retailers of REWE Group in Austria. Based on its current production infrastructure, the company can produce up to 12 mn protective masks per for the population and the medical sector. The monthly capacity for CE-certified FFP2 masks currently amounts to up to 5 mn pieces.

Guidance for 2020

The International Monetary Fund currently expects global economic output to decline by 4.4 percent in 2020, thus revising its forecast of June slightly upwards. The fiber market and the market for dissolving wood pulp came under considerable pressure in the first half of 2020, and especially in the second quarter of the year, as a result of the COVID-19 crisis. In the third quarter, the fiber markets recorded a noticeable improvement, which was associated with a positive development in demand and prices.

The further development will primarily depend on the impact of the COVID-19 pandemic on the global textile value chains and the effects on the consumer sentiment, as well as on the currency markets. From today’s perspective, the Lenzing Group assumes that the positive trend will continue in the fourth quarter and the revenue generation and operating performance in the fourth quarter will exceed those of the third quarter of 2020. However, if the number of infections should continue to rise and trigger lockdowns in more countries and regions in the coming weeks and months, this could have a negative impact on the revenue and earnings development of the Lenzing Group.

The comparatively solid business development in the first three quarters of the year reassures the Lenzing Group in its chosen corporate strategy sCore TEN. Lenzing will continue to implement its strategy with great discipline with a particular focus on the strategic investment projects which both will yield a significant contribution to earnings starting already from 2022.

[1] Attributable to Lenzing AG shareholders

1) Attributable to Lenzing AG shareholders

2) Capital expenditures: expenditures for intangible assets and property, plant and equipment and biological assets as per statement of cash flow

3) Ratio of adjusted equity to total assets in percent