#Yarn & Fiber

Lenzing turns commitment into action and launches carbon-zero TENCEL™ branded fibers to kick-start the decarbonization of the textile industry

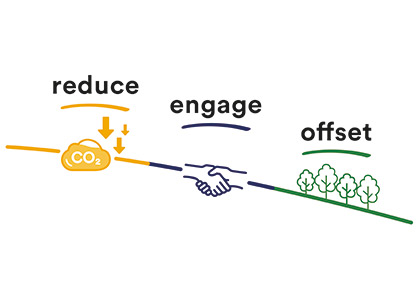

- The TENCEL™ brand is now going carbon neutral with a “reduce-engage-offset” approach, which helps to reduce the product’s carbon footprint, engage industry partners and offset unavoidable emissions to drive decarbonization in the textile industry.

- The TENCEL™ brand launches new carbon-zero TENCEL™ branded lyocell and modal fibers, certified as CarbonNeutral® products. The fibers will contribute to lower carbon emissions and energy consumption across the supply chain.

- As part of Lenzing’s longer-term “true carbon zero” campaign, four key levers will be deployed to cover energy reduction, renewable energy, new technology and supplier engagement to achieve carbon-zero in the long run.

Following the strict guidelines of The CarbonNeutral Protocol, the leading global framework for carbon neutrality, carbon-zero TENCEL™ branded fibers are certified CarbonNeutral® products for the textile industry. This means that the emissions associated with the fibers’ production, manufacturing and distribution have been calculated and offset. Under the guidance of the TENCEL™ “true carbon zero” campaign, the TENCEL™ brand is contributing to Lenzing’s commitment to the Science Based Targets (SBT) initiative and its continuous support of the United Nations Sustainable Development Goals to limit global warming.

To date, the Lenzing Group is the first wood-based fiber manufacturer with approved Science Based Targets in the industry. Lenzing’s goal is to reduce its specific greenhouse gas emissions by 50% by 2030. Available from September, the newly launched carbon-zero TENCEL™ Modal and Lyocell fibers are contributing to this target through reduced production emissions and its industry engagement to lower energy consumption across the supply chain. In addition to offering new sustainable options to the textile and fashion industry, the new carbon neutral fibers show a clear commitment to Lenzing’s earlier announcement of investing more than EUR 100 million in reducing carbon emissions in its operational boundaries and supply chain.

All-new fiber journey towards achieving carbon zero

Biodegradable and derived from botanic origin, fabrics produced using carbon-zero TENCEL™ fibers will have a third party verified label, offering a new level of sustainable transparency to Lenzing’s customers, brands and consumers. In addition to having a higher environmental value, the fibers will also feature the functional benefits of standard TENCEL™ branded fibers including gentleness on the skin, long-lasting softness, silky smoothness, enhanced breathability and color retention.

The introduction of the new carbon-zero TENCEL™ fibers is a key milestone in promoting the transparency of raw materials used in textile products. According to Lenzing’s Global Consumer Perception Survey on Sustainable Raw Materials in Fashion and Home Textiles conducted in early 2020, respondents indicated that they actively educate themselves on sustainability through research around the production process of products before purchase. Most respondents also considered brands that are transparent with their ingredients and the origin of their raw materials as trustworthy. These findings demonstrate the significance of raw materials, echoing Lenzing’s ongoing efforts to engage with its partners for new sustainable developments and educate brands and consumers on sustainability in textiles.

Committed to “Reduce”, “Engage” and “Offset” to support net carbon-zero by 2050

In late 2019, Lenzing pledged to reduce specific carbon emissions by 50% by 2030 and become net carbon-zero by 2050. Picking up on these commitments, Lenzing’s TENCEL™ brand is taking action via the pillars “Reduce”, “Engage” and “Offset”, which actively reduces the product’s carbon footprint, engages industry partners and offsets unavoidable carbon emissions.

With the priority of achieving continuous reduction of carbon emissions through more efficient production methods across the entire supply chain, using renewable energy sources and embracing new technologies, Lenzing is also working with the leading experts on carbon neutrality and climate finance, Natural Capital Partners, to achieve CarbonNeutral® product certification for TENCELTM Lyocell and Modal fibers. Natural Capital Partners requires an independent third-party assessment of the products’ carbon footprint and works with the highest quality carbon finance projects which produce verifiable, additional and permanent emission reductions that meet International Carbon Reduction and Offset Alliance (ICROA) approved standards. Furthermore, carbon-zero TENCEL™ fibers are produced using renewable energy, whilst also monitoring and engaging with suppliers.

Tom Popple, Senior Manager, Climate Change and Sustainability at Natural Capital Partners, commented: “By achieving CarbonNeutral® product certification for two TENCELTM fibers, Lenzing has taken an important step in its long-term journey to reduce its company and product emissions. Not only that, but due to the position of Lenzing in the supply chain of many fashion retailers, this certification sends a message of commitment to climate action for the textile industry. We are delighted to be working with Lenzing and look forward to supporting the company to achieve its future climate commitments.”

In parallel, the TENCEL™ brand is engaging industry partners and raw material suppliers to collaborate and empower brands to take part in the carbon neutral movement. To this end, Lenzing is the first cellulosic fiber producer to commit to the Science Based Targets initiative, as we engage and steer our industry to normalize supply chain transparency, source materials with low carbon footprint and thereby reduce overall carbon emissions.

Until carbon emission levels can be completely eradicated, the TENCEL™ brand will take actions to offset emissions by supporting verified global carbon reduction projects in areas that are linked to the textile industry, such as India, Bangladesh or Thailand. “We as a company and brand have taken steps to reduce our footprint, but not all emissions are avoidable. This motivates us to act on a global level and we found possibilities to help and support the avoidance of CO2 emissions around the world. The concept of carbon compensation through offsetting helps to contribute to carbon reduction through verified climate finance projects,” said Florian Heubrandner, Vice President of Global Business Management Textiles at Lenzing.

“In the midst of such a climate crisis, Lenzing believes that every company must take action against global warming within its sphere of influence. We are extremely excited to embark on this new initiative featuring CarbonNeutral® product offerings under the TENCEL™ brand. This is a new step forward for Lenzing’s overall corporate goal, enabling us to assist supply chain partners and motivate textile brands in reassessing carbon emissions in their production lines. Looking forward, we will continue to diversify our product portfolio following stringent internal guidelines that help to avoid greenwashing and involves consumers in the carbon neutral discussion,” said Florian Heubrandner.

Making a fundamental change in operations to reduce carbon emissions

Guided by Science Based Targets to facilitate the seamless transition of Lenzing’s carbon-zero journey, Lenzing will deploy four key levers that cover energy efficiency, reduction of fossil fuel use, integration of pulp and fiber production facilities and ongoing investment in new technologies to reduce carbon emissions.

“The launch of our carbon-zero TENCEL™ fibers is just the start of an ongoing battle against climate change. As we continue to innovate our production processes and fiber offerings, we will look beyond being complacent about the inherent climate advantage of the wood-based fiber business model. Our ultimate goal is to offer the carbon neutral benefit across our entire selection of TENCEL™ fibers and the textile supply chain,” says Robert van de Kerkhof, Chief Commercial Officer at Lenzing Group. “In parallel, we will continue to work with different partners, from brands and designers to NGOs, to build a more effective ecosystem that strives to achieve the common goal of carbon neutrality. While we continue to support our partners in their journey towards carbon neutral, we encourage everyone to join our ‘true carbon zero’ movement. With the clock already ticking, let us come together against climate change!”