#Weaving

Stäubli at Febratex

Febratex, taking place in Blumenau from August 23 -26, is the ideal platform to meet Stäubli (Booth 51/54, Area 4), a key supplier to the Brazilian weaving industry, supporting mills with adapted machinery and local sales & services.

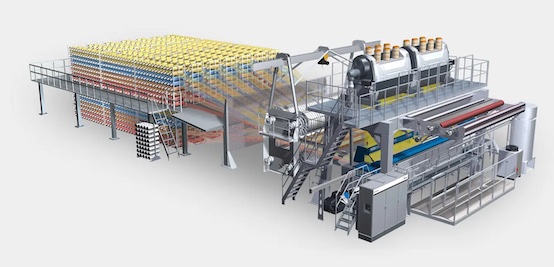

Stäubli machines feature state-of-the art technologies developed through 130 years of experience and a passion for continued research to bring even more advantages to every weaving mill. Visitors to Febratex will learn about Stäubli's latest highlight for Jacquard weaving: the brand new SX PRO Jacquard machine. This energy-efficient machine was recently launched at ITM 2022 in Istanbul and has already been installed in several weaving mills, performing reliably and efficiently.

By listening carefully to customers’ needs and applying its extensive market knowledge, Stäubli has long been a leading manufacturer of high-end weaving machinery. Market demands for air-jet and rapier weaving have been vigorous, and Stäubli has responded with a number of high-performance solutions, including its S1792 cam motion. This machine and the renowned S3000/S3260 electronic rotary dobbies come with e32/e33 transmissions that are engineered for high speeds, heavy loads, and long service life. Their maintenance-free bearings reduce oil and grease usage, decrease the time and cost of maintenance, and increase the reliability of the harness motion.

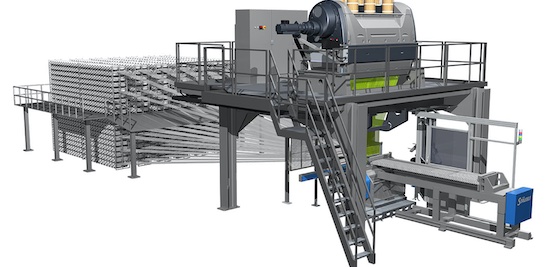

Both frame and Jacquard weaving require optimum weaving preparation in order to produce a maximum of first-class fabric and deliver on time. Raw material costs are rising, which is another reason yarn consumption should be optimized. Stäubli’s wide range of weaving preparation solutions includes machines and systems for high-quality warp and style changes. Since its launch at ITMA 2019, the TIEPRO tying machine has become the new must-have tying solution in many weaving mills. It provides easy handling and guides the operator through the delicate process of warp tying. Short knot ends make for easy drawing through during weaving start-up. And the machine requires no oil bath nor spare needles. Thus, it is not only a sustainable solution in terms of consumables but offers constant and high availability in the weaving mill for countless reliable warp changes.

Highly flexible and responsive partner responding to the mill’s specific needs

No matter how good a machine is, its full potential can be realised only through perfect operation. That’s why customer support is a top priority at Stäubli. As a consultancy partner, the company analyses the mill’s needs with the customer to choose the best machines and solutions to cost-effectively meet the stated goals. Stäubli’s experts are there to assist, from initial planning all the way through to final handover of the equipment. And after overseeing installation, testing, and fine tuning of the machinery, Stäubli trains the operators and production planning staff so that the mill is sure to derive the fullest benefit from the high-performance equipment. Highly competent service technicians complete Stäubli’s comprehensive service offer.

Febratex is an ideal occasion for weavers to meet with Stäubli in Brazil, discuss their challenges, specific needs, and projects, and learn more about how Stäubli solutions can benefit their weaving mills.