#Weaving

Data-based success for fabric manufacturers

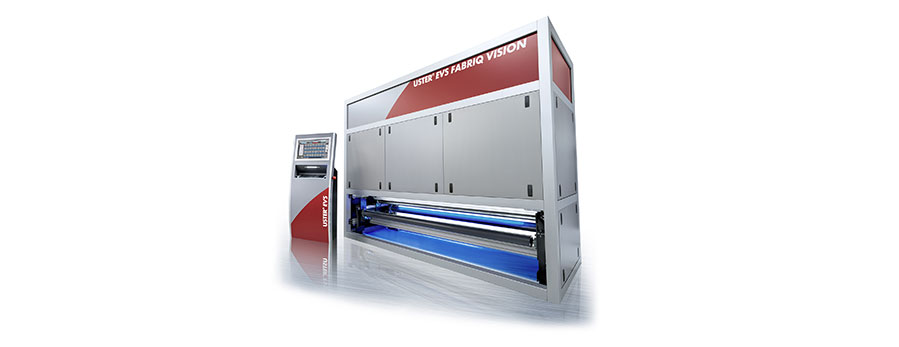

Automated fabric inspection delivers quality and optimization along the process chain

In a survey, customers reported that data from the Uster fabric inspection system was useful in quality assessment of the final product, as well as reports for customers. Traceability data was viewed as a particularly strong point for customers serving the automotive industry. Suppliers to this sector, and to other sensitive applications, value Uster EVS Fabriq Vision as a solution which meets the high standards of traceability, they need throughout the production chain.

Smooth and fast

Fabric producers need to guarantee reliable quality, which demands a consistently high rate of defect detection. Uster EVS Fabriq Vision ensures this is by using automated control during intermediate and final inspection, removing the need for manual inspection.

Multiple spectroscopes inspect the material. Unique image processing algorithms identify all defects automatically, recording them in a dataset for each produced roll – which is also used for traceability. A defect map is automatically generated, to help operators understand the allocation of defects in the fabric roll. This information is also available at an offline PC in the Fabriq Album software, which is a valuable tool for optimizing data for final cutting or further processing steps.

Effective – and people-friendly

A good investment shows up in spreadsheets for performance and sales – but it’s also confirmed by feedback from shopfloor personnel, as with Uster EVS Fabriq Vision.

Staff working daily with this fabric inspection system soon recognize that it’s a game-changer, because the inspection routine is increasingly automated. It works smoothly and quickly, in real time, checking every roll and locating every defect, at line running speeds.

Fabriq Album has even more people-friendly tools to make life easier for users. With manual classification, defects can be given customer-specific codes to identify each defect clearly. Unwanted images, or defects which can be ignored, can be removed automatically from the dataset, but are then retained in a hidden layer, for completeness of the dataset.

The future starts

The Fabriq Album software ensures optimum inspection efficiency and throughput. Machine learning capabilities and the implementation of AI-assisted defect classification extend the use of quality data generated by Fabriq Vision. Uster Fabric Inspection solutions bring the added benefit of helping customers to prepare for a digital future.

Uster’s use of Artificial Intelligence for automated fabric inspection was the subject of Michelle Salg’s talk at Techtextil Frankfurt. The Uster Product Manager for Fabric Inspection spoke in the Digitalization and Artificial Intelligence session, on June 22. Anyone who missed it can see all the details from her white paper available at uster.com/adc.

Data-based delivers

Leaders in fabric manufacturing – including knitters – can use Fabriq Vision to help make their own customers more successful. The key is the Fabriq Album. The whole finishing process contains different steps, sometimes executed by various companies. The dataset in Fabriq Album, generated by automated fabric inspection, is effectively a quality status report of process inputs, allowing manufacturers to manage all process steps for optimal output. Therefore, Fabriq Album empowers quality control and optimized end-products along the production chain.

The quality report, automatically created by Fabriq Album, can be provided to customers as an add-on, to give full transparency for every meter of the fabric. In technical textiles, and everywhere fabric inspection is needed – or should be – Uster Fabriq Vision can tap the potential to deliver major benefits for business.