#Weaving

High-tech behind historic walls: TextielMuseum in the Netherlands buys P2 rapier weaving machine from DORNIER

The official tourism website for the Netherlands says Tilburg, which lies about 100 kilometers south of Amsterdam, is a "cosy town". If you click through online travel guides, the city's textile museum is at the top of the list of recommended sights. It is part of the European Route of Industrial Heritage, which connects important historical economic sites in Europe. Located in a 19th century textile factory, the museum sees itself as a "dynamic and creative place". Not only knowledge about the history of the textile industry is passed on here, in fact the areas of design, art, fashion and innovation are interwoven within the construct of textiles.

Textile research in the museum

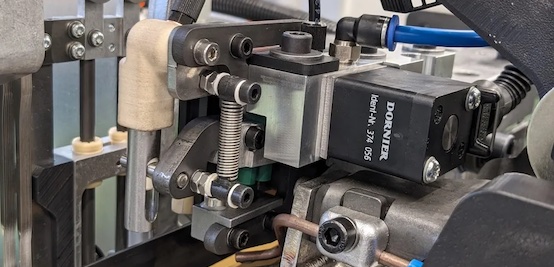

The "TextielLab" is connected to the museum. Here, students, architects, young artists and established designers from all over the world work on textile research, development and design projects using state-of-the-art technology. Recently, the museum's machine park was extended by a brand new P2 rapier weaving machine from DORNIER. Although the museum already owns three weaving machines, says Hebe Verstappen, head of the textile laboratory, the acquisition of the P2 "fulfilled a long-cherished dream", as the wide range of applications of the machine offers to innovative students, artists and designers completely new technical possibilities to realise their textile ideas and concepts.

Tapestries for exhibition in Bregenz

The first user of the new acquisition will be Otobong Nkanga. "I'm really looking forward to experimenting on the P2," says the performance artist, whose work has already been on show at London's Tate Gallery of Modern Art. The flexibility of the rapier weaving machines on which DORNIER's customers produce fabrics for home textiles, clothing and technical textiles opens up all kinds of possibilities for her to experiment with different yarns, colours and textures. The artist's first project will be a four-part tapestry series that will celebrate its premiere at a solo exhibition at Kunsthaus Bregenz, Austria, this autumn.

Woven creativity in today's world

DORNIER is proud to see the variety of creative woven innovations that are produced on the weaving machines from Lake Constance in the Tilburg "TextielMuseum", but also at many universities, research institutes and design studios. "Weaving is a textile technology that is over 10,000 years old. As a weaving machine manufacturer, we have seen a lot over the decades, but we never cease to be surprised at how great the diversity of ideas in fabric production still is," says Florian Boch, Head of Central Marketing and Communication at DORNIER. The P2 has also been very well received by DORNIER's industrial customers since its introduction in 2019. Weaving mills in Europe, Asia and the USA are ensuring very satisfactory sales figures despite Corona's impact on the global economy. According to the family-owned company DORNIER, this is mainly due to the fact that the P2, as the successor to the rapier weaving machine introduced in 1967, continues to demonstrate its quality as the most flexible rapier weaving machine in the world, which is much-vaunted in expert circles.