#Weaving

Itema signs the contract with the Egyptian Cotton & Textile Industries Holding Company C.T.I.H.

The program, entrusted to the Cotton and Textile Industries Holding Company C.T.I.H. and supported directly by the President Mr. Abd El fattah El Sisi and by the Minister of Public Enterprises Hisham Tawfik, consists in setting up a state-of-the-art, fully vertically integrated textile park encompassing spinning, weaving, knitting, dyeing, finishing, printing and confection which will represent the largest regional sourcing hub in the Mediterranean Region.

The project, worth approximately EUR 1 Billion, will establish a new benchmark for the whole Egyptian textile industry by increasing the competitiveness of the country. In fact, the never-before-seen project is going to upgrade the Egyptian textile industry production capacity and will further unleash the value of one of the country real treasures, the cotton, worldwide known as “White Gold”.

The program has been launched in 2019 and the first phase of the supply process has been finalized during ITMA Barcelona, when the Cotton and Textile Industries Holding Company C.T.I.H.C announced the pool of suppliers selected to execute the project, which included Itema.

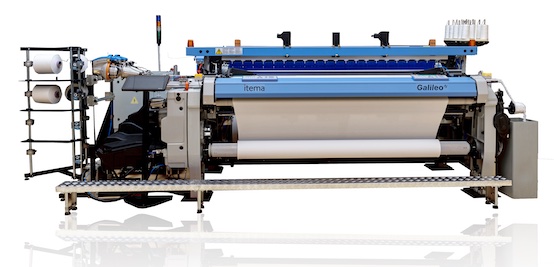

In October 2020, during an official meeting with Dr. Ahmed Moustafa – President of the Cotton and Textile Industries Holding Company, Itema – along with its sole agent in Egypt Fabtex Agencies and Trade represented by its owner and CEO Eng. Kamal Abbas – signed the contract for the supply of 654 weaving machines that will operate in the production plants of Mehalla El Kubra, Kafr El Dawar and Damietta.

Commenting the successful outcome for Itema, Mr. Ugo Ghilardi, Itema Group CEO stated: “Itema is honored to be part of this historic project, that represents a real excellence center not only for Egypt, but for the whole Mediterranean Region. The Cotton and Textile Industries Holding Company C.T.I.H.C will find in Itema a partner, and not a common supplier, who will ensure the supply of the most advanced weaving technology and a full range of solutions and services to make this project a real success. Actually, we recently celebrated the opening of the textile park in Robbiki, where Itema has been appointed as weaving machines supplier by the Egyptian Army and we look forward to seeing running live the Itema looms in this new epic project. These bulk orders make us feel proud and demonstrate to the textile industry that Itema is the ideal partner to maximize the return of investment”.

Itema is traditionally present in the Egyptian market, where the Italian Company has been providing weaving machines for the production of a wide range of fabrics for a long time, from furnishing to denim and shirting, passing through apparel and bed sheeting. Mr. Ferdinando De Micheli, Itema Group Sales Director commented. “Egypt is the cradle of the most precious cotton in the world and the textile industry represents one of the most important sectors in the country.?As Itema, we historically value this market, just consider that in recent years we supplied around 1000 weaving machines to the Egyptian private sector. We feature in our portfolio all type of weavers, from the smaller artisanal companies to the largest worldwide renowned mills providing to all of them the same excellent dedication. Now, with these important and colossal orders, we put our signature on projects that are set to change the shape of the textile industry in the area.”

The Cotton and Textile Industries Holding Company C.T.I.H.C modernization program will be implemented in 2021 and 2022, when the weaving plants in Mehalla El Kubra, Kafr El Dawar and Damietta will be equipped with the 654 weaving machines from Itema.