#Weaving

KARL MAYER’s PROWARP® and MULTI-MATIC® 32 impress the market

The MULTI-MATIC® 32 is a highly productive warping machine for the production of sample and production warps with short running length, which is particularly well received by manufacturers in the high-quality fashion sector. Both machine types have already been sold several times worldwide.

PROWARP®

The selectable, innovative solutions offered by the PROWARP® configuration include PROACTIVE warping, a system for optimising warp beam quality that will be cloudbased in future. The new development comprises a total of three levels and the amount of information increases with each one. Level 1 provides protocols with data on warping or beaming quality, which are supplemented in level 2 by active quality management with a customer-defined star rating. This extension level also offers the possibility of integrating a modern high-resolution camera system. The innovative solution records measurements including the band width and band set-up – i.e. the distance from band to band or to the cone. In addition, level 3 offers evaluations and diagrams for the single thread tensions of the optional MULTIGUARD yarn stop motion. In levels 2 and 3, the data is also exchanged with the KM.ON cloud via the KM.ON device k.ey. Using cloud networking, a real-time machine dashboard can be created and, in future, it can be synchronised with new start parameters via an algorithm. If deviations occur, production data can be optimised and adopted for repeat orders if desired. This allows the beam quality to be improved, regardless of the operating personnel.

Further systems for ensuring high product quality relate to regulating the layer thickness during the sectional warping process. To do so, either the yarn tension at the creel exit or, if available, the speed of the yarn feeding elements is adjusted. Fine adjustment is triggered by measured values taken from the layer thickness of the individual sections, which are continuously recorded by laser in a contactless manner and compared with the values of a master section. PROWARP® ensures a high degree of quality reproducibility with well-thought-out solutions to manage orders and production data.

Flexible use, best performance values

In addition to product quality, the PROWARP® is also efficient. An innovative order management system not only enables weaving mills to be up to 5 % more efficient and performance to be increased by up to 30 % in weaving preparation compared to standard market counterparts, but yarn waste is also reduced. A high degree of application flexibility completes the PROWARP® performance package. The new high-performance sectional warping machine is suitable for all material types and combinations, and guarantees a constant winding build-up over the entire yarn spectrum.

It manufactures production warps that are used in technical and standard applications. It has a special configuration to produce warp beams for technical woven fabrics, determined by the suffix “HT”. For the apparel and home textiles sector, PROWARP® offers warp beams for creating detailed patterns and designs of different colours. To meet the wide range of applications, the PROWARP® is designed for pulling forces of up to 40,000 N and has a working width of up to 5.6 m. It reaches a maximum speed of 1,000 m/min for warping and 500 m/min for beaming.

Model change by 2021

Since its launch as a series model at ITMA 2019, the PROWARP® has been ordered by around ten manufacturers. Orders predominantly came from the technical sector and mostly from Europe; their market distribution will also see a slight model change. KARL MAYER’s Warp Preparation Business Unit plans to merge the ERGOTEC and OPT-O-MATIC product lines and gradually replace them with PROWARP®. “We plan to complete the model changeover next year,” said Development Manager Martin Fuhr. Exceptions will, of course, be possible.

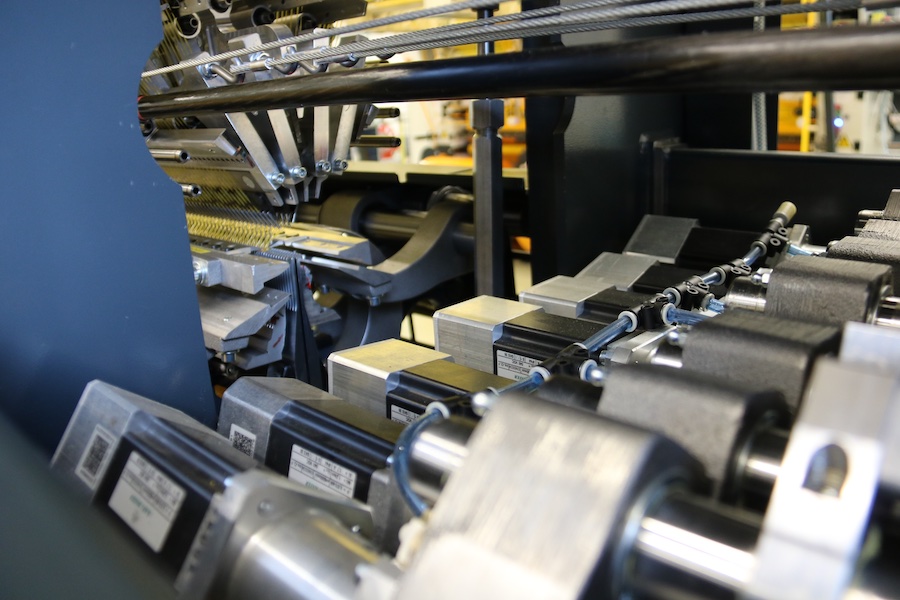

MULTI-MATIC® 32

The MULTI-MATIC® 32 particularly stands out thanks to it excellent price-performance ratio. With the benefit of eight pattern threads, the single-end warp sampling machine offers a third more performance compared to the previous model, but without costing more. It is most efficient at run lengths of 200 to 400 m. When equipped with KAMCOS® 2, the MULTI-MATIC® 32 can be digitally networked via an integrated OPC-UA interface, which means operating data can be gathered in real time. In addition, the reduced number of bobbins allows for a smaller creel, which can be equipped with rollers and arranged differently depending on the yarn quality. The innovative MULTI-MATIC® 32 was designed to replace the GOM-24. It processes bobbins with greater yarn volume and thus with longer change intervals than the model in the GIR-O-MATIC® series, which cuts handling effort and yarn storage costs. Overall, the priceperformance ratio of the MULTI-MATIC® 32 is up to 30% better than that of the GOM-24. The MULTI-MATIC® 32 also stands out when compared with the sectional warping machine, another adjacent model in KARL MAYER’s product portfolio: the low number of bobbins means that there is no need to split them up by rewinding them onto several bobbins.