#Weaving

Fighting corona: DORNIER supports its customers in the change of production to face masks and protective clothing

In the fight against the corona virus, more and more textile companies switch their line of production to urgently needed protective gear and face masks. As these can be woven on both, DORNIER rapier and air-jet weaving machines, Lindauer DORNIER actively helps its customers to potentially adapt the manufacturing process to the current requirements.

"These are challenging times for all of us. As a family-owned company, we want to work together with our partners as well as customers and find solutions to protect people from Covid-19 and slow down the spread of the disease," Head of the Technology Center in Lindau, Lars Öller says. This has a double effect: in addition to protecting patients, healthcare professionals and citizens, companies can use idling capacities and partially compensate for lost revenues due to the crisis.

Face masks as precise as airbags

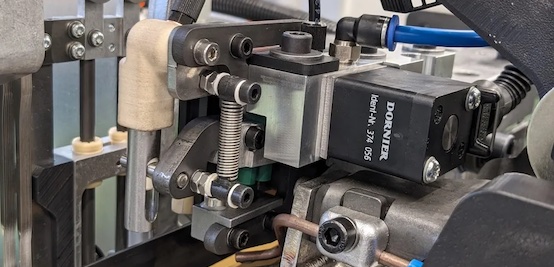

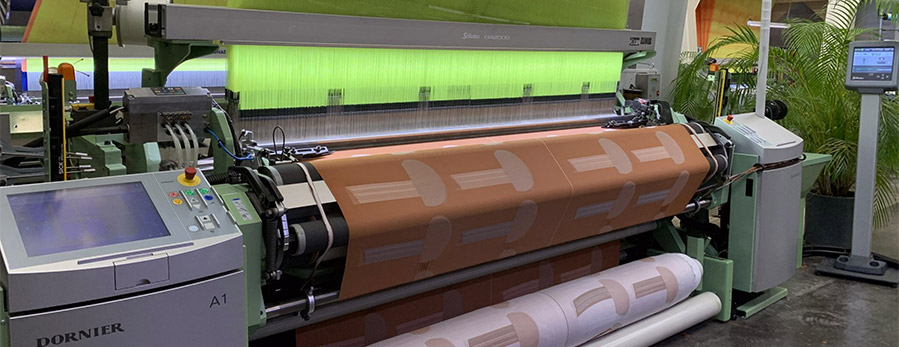

The DORNIER system family is suitable for the fast, simple and process-reliable production of face masks made of cotton or polyester for example. On air-jet weaving machines type A1, life-saving face masks can be woven in one piece as “One Piece Woven” and then be laser cut into the desired shape. Two thirds of all airbag cushions worldwide are produced in this way. Identations and structures to insert filters and valves can also be integrated to further increase the effectiveness of the masks. Antimicrobial materials such as silver threads might further increase the protective effect.

Faster certifications, designable fashion

To facilitate placing corona protective equipment on the market, measures have been taken in many places to speed up and simplify conformity assessment procedures. The textile face mask is now even becoming a global fashion trend, possibly even beyond the corona crisis: more and more designers are taking it up as an individually designable fashion accessory.

VIDEO: