#Weaving

COMSAT opts for the Eltex EyETM

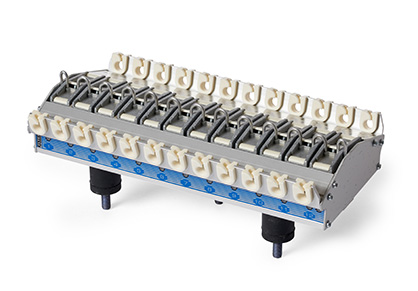

Unlike yarn tension monitors that are fitted solely on the weft insertion systems of weaving machines, the new Eltex technology is for the warping process prior to weaving – and instead of monitoring only the tension of the six-to-eight yarns fed by the weft insertion system the Eltex EyETM keeps a close eye on literally hundreds.

“Several hundred yarns can be fed from the creels during the warping process compared to only a few weft insertion yarns during weaving,” explains Brian Hicks, managing director of Eltex. “Tension monitoring for multiple ends has been a great challenge to achieve for us, but this new system generated tremendous interest at the recent ITMA 2019 textile machinery show and we already have systems in operation and orders on hand. The EyETM allows mills to greatly reduce problems.”

“With warping that can operate at high speeds, the yarn tension values from all yarns are continuously updated and displayed on the screen,” adds Isabel Mataró managing partner at family-owned COMSAT. “Tension values outside the warning level are indicated both on the sensor’s LEDs and on the screen. This greatly increases yarn evenness and subsequently the woven fabric quality. In addition to being fitted on our latest Tecmat machine, the Eltex EyETM can also be retrofitted to existing COMSAT machines already in operation.”

In business for over 70 years, COMSAT (Construcciones Mataró Servicios y Asistencia Tecnica) is a specialist in textile machinery for weaving preparation, including sectional warping machines and creels, auxiliary machinery, inspection machines, batching units and selvedge warpers.

Eltex is headquartered in Osby, Sweden, where it primarily carries out its research and development work. A North American sales and service subsidiary operates from South Carolina and the company’s manufacturing plant has been located at Templemore in Ireland since 1977, providing significant advantages in terms of high flexibility and logistical services to customers on both sides of the Atlantic.

Eltex is a member of TMAS – the textile machinery association of Sweden.

“As far as sensors are concerned, Eltex of Sweden is achieving considerable success with its yarn fault detection and tension monitoring systems across a range of sectors, including the tufting of carpets, the creeling of woven materials and even the production of woven reinforcements for the composites industry,” said TMAS Secretary General Therese Premler-Andersson. “Unlike scanning inspection systems, Eltex is monitoring each individual yarn position in real time, and as a consequence has concentrated on the further miniaturisation of its sensors, as was conclusively demonstrated at ITMA 2019.”