#Weaving

Celebrating 60 years at Eltex of Sweden AB

That the company’s timeline aligns with the acceleration of weaving machine production speeds from around 150-200 picks per minute back in the 1960s to up to 1,200 picks per minute today is no coincidence – Eltex sensor technology has made a significant contribution to enabling today’s fault-free, high-speed production.

Modest beginnings

The electronic detection of broken or missing weft yarns during production was the problem Eltex founders Åke Rydborn and Ragnar Henriksson set out to solve with the development of the world’s first electronic weft-stop-motion.

Its potential was instantly recognised on its introduction at the 1963 ITMA exhibition in Hannover, Germany, leading to the foundation of the company in a modest 12-square-metre workshop in Älmhult, Sweden, in February 1964.

By 1968 the company was operating from a modern 3,000-square-metre plant and beginning to establish a global presence, introducing the first all-in-one printed circuit board (PCB) for its sensor systems in 1971.

“There were no electronics experts in the mills back then and only a few working for the machine builders themselves,” remembers Alf-Gunnar Sibbeson, who has worked for Eltex for many years from 1971 onwards. “As a consequence our servicing was very much in demand, because if problems occurred, nobody else was able to solve them.”

Expansion

As exports increased, further Eltex operations were established in the USA and Ireland and the company expanded its product range, for a time in its history, to include energy control devices, temperature and humidity loggers, food handling safety systems, and military grade battery chargers.

Further textile milestones in parallel to advances in weaving technology included optical arrival detectors for air-jet weaving machines at the beginning of the 1980s, and the QTV system for warp preparation, which introduced digital stop-motion control to the industry at the start of the 1990s.

In 2009, the company branched out into carpet tufting, first with the CoTS clamp-on tube sensor for tufting machines, followed by the Compact sensor for tufting machines in 2013 which was an instant success. In 2019 the Compact II further cemented the company’s position in this sector.

Newly developed Eltex EyETM and ACT-R

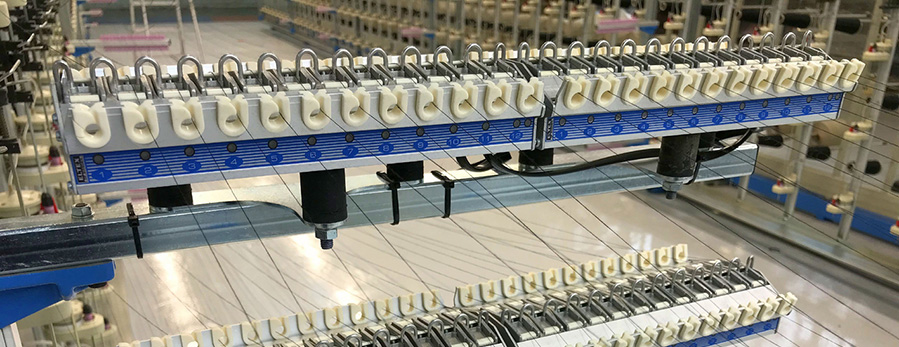

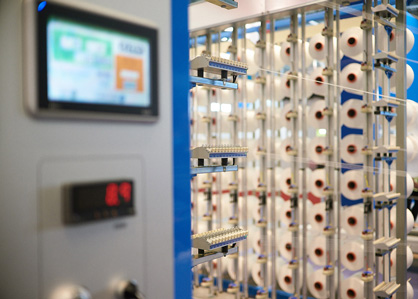

Most recently, Eltex has launched the Eltex EyETM system for the continuous monitoring of yarn tension on warp beams. Not only does it eliminate problems when warping, but also in the subsequent weaving or tufting processes. Eltex EyETM monitors the yarn tension on all positions in real-time and a minimum and maximum allowable tension value can be set. If any yarn’s tension falls outside these values the operator can be warned or the machine stopped.

The Eltex ACT and ACT-R units meanwhile go beyond yarn tension monitoring to actually control yarn tension. This extends the application range greatly. The plug and play system automatically compensates for any differences in yarn tension that arise, for example from irregularities in yarn packages.

Resilience and dedication

“In today’s highly optimised textile production environments, yarn tension has become an important parameter in eliminating faults and ensuring premium quality at all times,” says Eltex CEO Brian Hicks. “As we celebrate our 60th anniversary and continue on our journey, I’d like to thank all staff for their resilience and dedication, and also our customers and suppliers for the fruitful partnerships we’ve established together over the years. At Eltex, we will continue to focus on customer service, adapt to changing landscapes and work to pioneer technological advancements.”

Eltex has been owned by Brian Hicks, Seamus O’Dwyer and Jonathan Bell since 2007, following a management buy-out and the subsequent formation of Eltex Global Holdings in Ireland. Today, its head office, Eltex of Sweden AB, is in Osby, Sweden where it provides research and development, administration and global sales for the group. Eltex Manufacturing in Ireland is now the group’s primary production facility and Eltex US, Inc. provides sales and service for North America.