#Weaving

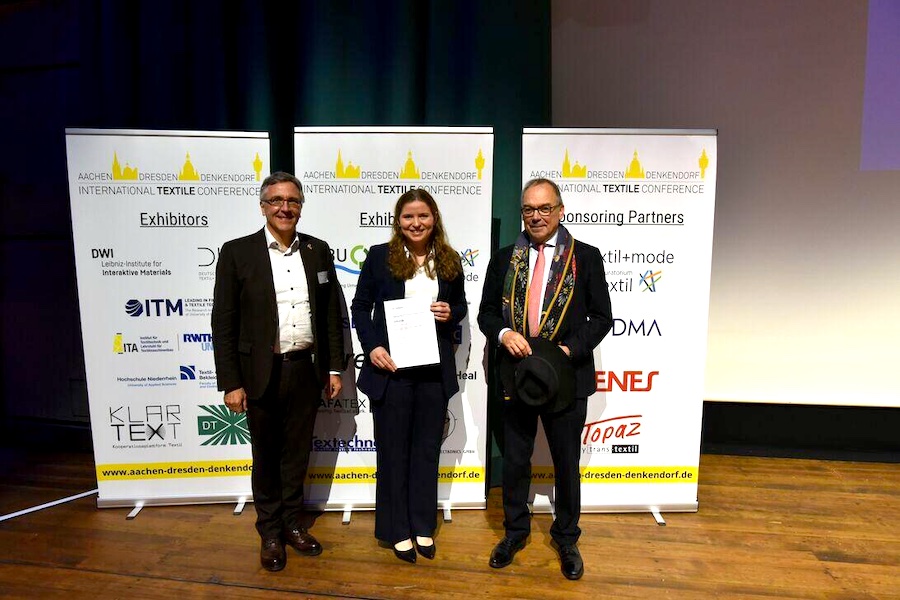

Vandewiele present at DOMOTEX TURKEY 2019!

And it’s the perfect place to present our latest developments and products to the carpet industry.

Vandewiele, expert in yarns

The final quality of a carpet is mainly dependent on the quality of the yarn being used. Vandewiele’s experience in woven and tufted carpet, combined with the technological know-how of efficient yarn production, has led to the development of our current line of extrusion equipment.

After extrusion, yarns are often cabled and heatset. The French company Superba, part of Vandewiele, is since many years a world-leading manufacturer of heatsetting equipment. The Superba equipment uses a unique and highly performing system using saturated steam as to set many different kinds of raw materials including polypropylene, polyamide, acrylic, PET, wool,…The space-dyeing machine which allows printing a random pattern of colours on the yarn is already a big success. It gives the developer endless possibilities to create new and interesting designs which can be used in woven as well as tufted carpet qualities. And the success story continues with the introduction of new Multicolored BiColor Frieze (Textured) yarns that will open new opportunities for carpet designers.

Colortec

The Most flexible Tufting system on the market.

Wide Variety of “jacquard designs” for carpets and rugs, available in 5/32”, 1/7” or 1/10”

With the Colortec and its ICN technology, the Individual Control Needle, a higher efficiency and quality will be reached. It will only tuft pile where required and therefore saving yarn for shaped carpets. Moreover, this allows you to tuft with “weaker” yarns (e.g. wool), less yarn on the back and this up to 12 colors and multiple color mixes.

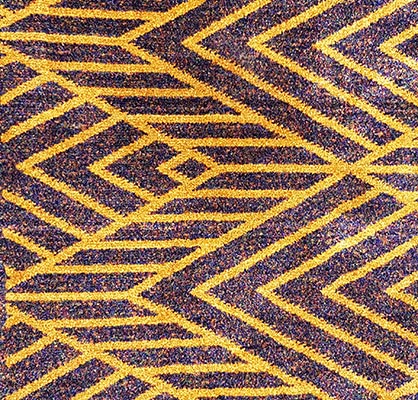

The HCiX2 Handlook Carpet Innovator is a high density carpet weaving machine using the patented three rapier weaving technique with stationary incorporated pile yarns, giving a clear back, less incorporation and a higher weaving efficiency. The design on the pile side is crystal sharp. There are no visible warp yarns on the backside, which makes the carpet look like real handknotted.

The HCiX2 carpets in acrylic, viscose, polyester,… are woven with optimized efficiency. Designs in the border, filling effects and natural fringes are all possible.

Our newly developed handlook carpet weaving machine has a reed density of 1500 d/m in 8 pile frames. With this execution of the HCiX2, carpet qualities up to 5.000.000 pile points per square meter are reached!

We are excited to announce the launching of the fully redesigned, mobile-responsive website of our Vandewiele site where you can find a complete overview of all our brands and products.