#Textile processing

Groz-Beckert needle handling solution – proven in practice

The INH Quality Management stands the test in leading garment factories

Groz-Beckert’s patented INH (Ideal Needle Handling) Quality Management is already in use in many garment factories all over the world. The feedback given by the customers is consistently positive. It is not only the fact that INH ensures a high level of safety and enables simple and efficient processes that is a great advantage. The fact that all information is available in digital form and that data-driven analyses and optimizations can be carried out is also an important reason for garment manufacturers to implement INH. Well-known companies like SPEIDEL (Germany) and DoLuong (Vietnam) are more than satisfied with INH.

Solution in practice

Needle breakages are unavoidable in ongoing production. But a needle change takes time and it is important to ensure that all broken needle parts are found and that all needle breakages are documented. Thanks to INH work and time required for the search and documentation of broken and damaged needles are reduced what results in increased work performance – also avoiding downtimes in production. The fully digitalized documentation eliminates the need to stick needles on paper saving resources and enabling environmentally friendly disposal of the needles. The digital documentation also enables a data-based analysis of the needle consumption and reveals potential for improvement by identifying problems such as incorrect machine settings or the use of the wrong needle.

How it works

The main element of INH is the needle dispensing trolley, which can replace the complete needle dispensary. The trolley stores not only new needles and various tools that can be used for the search for needle fragments but is also the collection point for used and broken needles. All needle changes are documented directly on the trolley via the app INH@site.

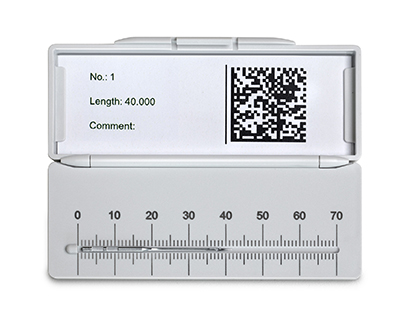

Another accessory is the needle return box. This is used for collecting and returning broken and damaged needles. The inlaid needle pass contains all relevant details for the digital documentation of the needle change.

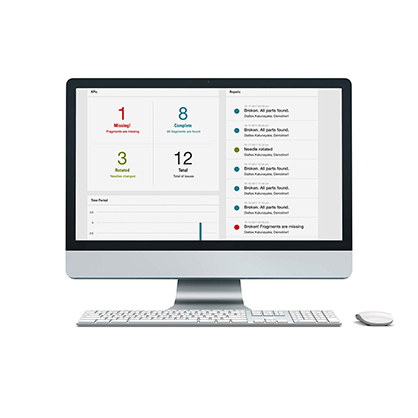

The digital solution for the documentation of all needle changes is INH@site and INH@office. The INH@site app – installed on a tablet on the trolley – is used to photograph used and broken needles and to carry out the documentation. The images and datasets created in this way are transmitted to the INH@office browser application. They can be accessed and viewed there. INH@office is also used to maintain and administer all relevant data, such as production orders, sewing lines and machine inventory. And last but not least, buyer audits can be executed online, as they can access all information at any time and without great effort.

Reassured day by day

All in all, INH Quality Management by Groz-Beckert offers reliable and standardized processes that take into account both internal requirements and the buyers’ compliance regulations resulting in a stronger relationship to the buyer.

Still, the most severe thread are end users sustaining an injury from pieces of a broken sewing machine needle left in the garment. Such incidents can lead to compensation claims and loss of orders from brand owners and buying houses. Managing needle handling with INH can reduce this risk significantly.

The INH Quality Management has been successfully implemented by many garment factories worldwide. It enables an individual process to be set up that takes into account both the previous procedure in the factory and the buyer’s compliance regulations. During uncountable working hours on hundreds of production lines and at thousands of sewing machines INH puts customers at ease with best-in-class needle handling – and gains trust from big brands.

Read more about INH and Groz-Beckert customer stories in the Customer Portal under Groz-Beckert Sewing Portal or contact us under contact-inh@groz-beckert.com.