#Techtextil 2024

Reliable weaving in challenging times: DORNIER presents solutions for future-proof fabric production at Techtextil

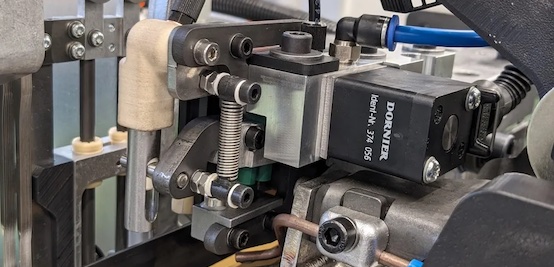

Rapier weaving machine P2: Revised control panel & new cloth winder

In Frankfurt am Main, the machine and system manufacturer will be presenting a series of developments for the rapier weaving machine P2. These include the revised interface for the DORNIER ErgoWeave® Dialog Panel. Its user interface has been designed to be more intuitive, making it easier to keep an eye on machine parameters, article and pattern data in future. The new Electronic Cloth Winder (ECW) for the P2 will also be presented at Techtextil. In the ECW+ version, it enables fabric manufacturers to precisely define the winding force over the fabric length and thus have full control over the quality of the fabric from the warp to the final fabric. The new ECW winder can be retrofitted to existing P2 rapier weaving machines from DORNIER. Thanks to the unique shed geometry, the higher weft insertion rate, the maintenance-free drive from our own production and the – compared to the predecessor model P1 – optimized active center transfer of the weft yarn, the P2 is becoming increasingly popular with fabric manufacturers in the clothing, home textiles and technical textiles sectors. "Manufacturers who can react quickly to market changes with the reliable and flexible weaving machines from DORNIER have a decisive advantage in challenging times," says Wolfgang Schöffl, head of productline for weaving machines at DORNIER.

Air-jet weaving machine A2: Intelligent production monitoring

Further developments to the A2 air-jet weaving machine, which was officially launched on the market last year, will also be presented at the trade fair. These include developments to the electronic control systems, such as electronic pressure regulation (EPR) significantly increases the process stability of production. Or the intelligent Electronic Valve Control® (EVC+) algorithm, that automatically monitors and controls the nozzle valves. Electronic Pressure Monitoring (EPM), which monitors the pressure level on the A2 air-jet weaving machine and thus significantly increases production efficiency and reduces downtimes, will also be presented in Frankfurt. "This form of intelligent production monitoring is a basis for measures to sustainably reduce energy consumption," explains Schöffl.

More efficiency through networked fabric production

The networking of DORNIER air-jet and rapier weaving machines for even more convenient management of fabric production will also be the focus at Techtextil. With the new PC programme DORNIER DoXWeave, data from DORNIER weaving machines can be managed, read out, compared and created. The DORNIER DoXNet networking solution connects weaving machines in one or more weaving sheds to form a machine network. The software provides the user with a simple overview of the current status of all connected weaving machines via a browser-based dashboard. The DoXNet server programme runs on the company's own network infrastructure and does not require Internet access. The customer therefore has full control over sensitive production data. This not only shortens set-up times, but also optimizes the reproducibility of the fabrics. To make data management more user-friendly, the user interface of the Dialog Panel for weaving machines A2 and P2 has been redesigned and is now more intuitive. Trade visitors can also find out about recent developments in the myDoX® customer portal with its 24/7 online shop for original parts (powered by SAP HANA).