#Techtextil 2022

ITA at Techtextil 2022

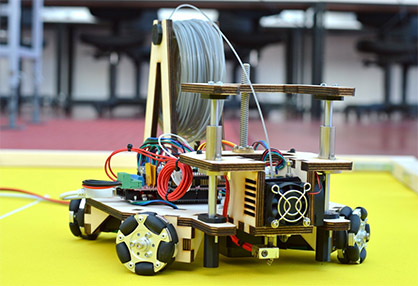

1. 3D printing robot on textiles - experience it live in Hall 12.0 B55!

The 3D printing robot is a mobile and size-independent 3D printer for large-area components on textiles. For the first time, a 2.5D support structure can be printed on a textile with such a printer. Please find further information here:

https://techtextil.messefrankfurt.com/frankfurt/en/exhibitor-search.detail.html/institut-fuer-textiltechnik-der-rwth-aachen-university-ita.html

2. Recycling rope

The recycled rope is a climbing rope that consists of 50 percent recycled rope production waste and is available on the market. Example of textile to textile recycling in PPE. ITA has developed 100 percent recycled, high-strength filament yarns for the rope.

3. CO2-sock

The CO2-sock is made of elastic TPU fibres, which are produced on the basis of CO2-. This results in a reduction of the carbon footprint. ITA has developed a melt spinning process for this special polymer, which is currently being scaled up to industrial scale. By reusing carbon dioxide from industrial waste as a raw material for textile and clothing products, the carbon footprint is improved.

4. Teddy bear with scarf made from recycled acrylic waste

The teddy bear wears a knitted scarf around its neck that is made of 50 percent recycled waste from blanket production using PAN fibres. In addition, intermediate products from all process steps of the solvent-based reprocessing of the waste are used in the production of this knitted fabric.

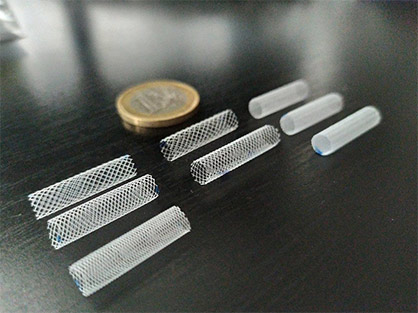

5. Bioresorbable stent

The most common materials for wire-based vascular stents Nitinol or Elgiloy can cause long-term problems such as thrombosis and other complications. In contrast, bioresorbable stents can perform their structural function for the required time (e.g. a few months) and then be resorbed without causing adverse reactions in the patient.

Detailed information on the above-mentioned exhibits can be found here:

https://techtextil.messefrankfurt.com/frankfurt/en/exhibitor-search.detail.html/institut-fuer-textiltechnik-der-rwth-aachen-university-ita.html

Please find these and other exhibits on our stand in hall 12.0 B55.

You will also find information on our stand about the opening of the Recycling Atelier of ITA Augsburg and Hochschule Augsburg University of Applied Science on 20 June 2022 in Augsburg. The Recycling Atelier represents a centre for research and development along the entire textile production chain for textile recycling and thus makes a decisive contribution to the transformation of the linear economy to the circular economy.

A virtual opening will follow at the VDMA stand at Techtextil 2022 in Frankfurt on Tuesday, 21 June 2022 at 14:00. For the virtual opening at Techtextil, please register under WEB-/SPOTLIGHT TALKS at www.industryarena.com/m4t.

We will inform you about our current degree programmes at a second booth in Hall 11.0 A10.

We look forward to your visit!