#Techtextil 2019

Automatic control and mill-proven benefits for quality and profit

Technical textile producers report practical gains with USTER® EVS fabric inspection systems

Automated visual fabric inspection is an essential asset in optimizing quality for a wide range of technical textiles and performance apparel. Applications in architecture, automotive, construction, hazard protection, medicine, aviation and aerospace have some of the most stringent quality criteria. But fabrics for furnishings, sports and functional clothing must also meet the perfect standards that major brands need to uphold their reputation and satisfy customer expectations.

All fabric producers aim to deliver the quality their customers specify, while also minimizing scrap and seconds to protect their own efficiency and profitability. The different fabric production and finishing processes contain plenty of opportunities for fabric faults to arise. USTER’s automated fabric inspection system bring quality under control, regardless of the complexities of the manufacturing stages. Fallible human judgment and varying levels of operative ability and experience are no longer critical to the production of consistent, reliable quality. Accurate automatic quality control becomes an integral part of manufacturing.

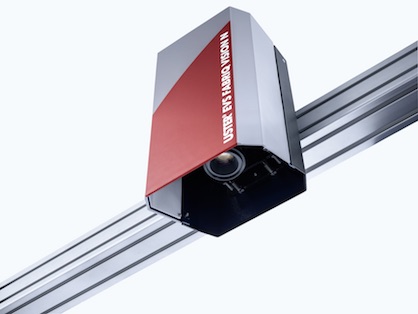

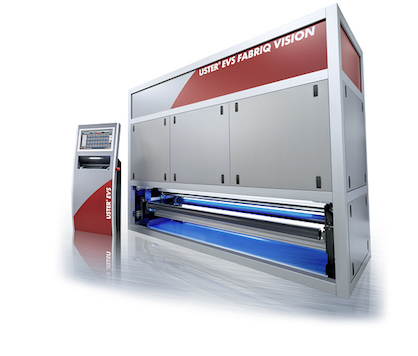

Early-stage control with USTER® EVS Q-BAR eliminates the need for manual inspection after production. USTER® EVS FABRIQ VISION ensures reliable monitoring, using automated control during intermediate and final inspection. The system’s ability to capture any visible faults – with a proven and consistently high rate of defect detection – and its optimized fabric grading protect the producer from the risk of damaging claims.

Dyed fabrics present the particular extra challenge of color uniformity. USTER® EVS FABRIQ SHADE has the solution, monitoring in-line shade variation in virtually any process where color is critical, without the need to cut fabric swatches for laboratory tests.

Optimizing profit

Automatic fabric inspection is the way to achieve optimum quality, to reduce below-par and scrap fabrics and to maximize fabric yield. The cut optimization software module of USTER® EVS FABRIQ VISION and USTER® EVS FABRIQ SHADE optimizes fabric yield per class, according to the settings. The system works by marking any defects in the fabric during inspection. The position of each defect is synchronized with Optimized Cut Control (OCC), which stops the cutting table at precisely the right place, guaranteeing error-free cutting. OCC can also identify and highlight defects which require operator action, making the process more efficient.

Only one operator is needed to oversee the entire production, reviewing defects and rejecting or accepting them. The system is self-learning, reducing unnecessary alarms over time. The operator sends the fabric roll, with its defect report, to the cutting station, where faults can be marked, mended or removed as required. This saves time, as the operator has only to manage roll processing, rather than actually inspecting the fabric.

Proven results

USTER® EVS automatic fabric inspection technology is founded on more than 25 years of pioneering development in the field. Today, more than 1,000 installations in wide-ranging textile segments worldwide acknowledge it as the key to cost savings and enhanced market competitiveness.

USTER® EVS customers currently inspect over 60 million meters of fabric per day. Many companies which installed EVS lines in the mid-Nineties have recently upgraded their automatic fabric inspection systems with USTER® EVS FABRIQ VISION and USTER® EVS FABRIQ SHADE.

Some users have provided valuable feedback on major benefits of the systems. A German fabric finisher reports that in the first six months after installation of USTER® EVS FABRIQ VISION, it was able to produce 1.2 million meters of fabric without a single customer claim. Another firm, a European leader in protective clothing, purchased two systems of USTER® EVS FABRIQ VISION and USTER® EVS FABRIQ SHADE in 2017. As well as reducing claims, the company also managed to decrease labor costs by saving 14 operators.

An Italian customer installed USTER® EVS FABRIQ VISION and USTER® EVS FABRIQ SHADE alongside automatic cutting and packaging machines, replacing manual inspection. Within three years, off-quality and scrap decreased by more than 3%.

For more details and to discuss individual requirements, interested parties are recommended to meet the experts at Techtextil. Fabric producers and finishers are welcome to present booth staff with any challenges regarding automatic fabric inspection at the forthcoming event, in Frankfurt, Germany, from May 14 to 17. The USTER® EVS Q-BAR, as well as other members of the USTER® EVS fabric inspection family, will be presented. Visit USTER at booth D05 in Hall 3.0, together with German agent Elmatex.