#Technical Textiles

Technical textiles for more and new business

KARL MAYER Technical Textiles presents innovative textile solutions for construction and filtration at ITMA ASIA + CITME

Clean solutions for filtration

The filtration solutions ensure purity, efficiency and taste and are based on the membrane principle. Hollow fibre mats with porous outer surfaces are used. Gases and impurities are transported across these surfaces while the feed medium flows through the fibres. This principle can be used to enrich the preliminary product with oxygen and carbon dioxide during beer brewing, to degas ink for printer cartridges, to decarbonise ultrapure water, and to enrich blood with oxygen or purify it by means of dialysis, to name just a few of the many applications of hollow fibre membranes in industry, beverage production and medicine.

The mats are manufactured to strict specifications for their demanding applications. The hollow fibres must not be crushed, constricted or stretched and must be arranged evenly at a high density – a task tailor-made for the WEFTTRONIC® II RSP WEFT. The sophisticated technical solutions of this Raschel machine with weft insertion ensure high stitch densities of up to 25 M/cm with low knitting yarn tension. This is important for the loose binding of the hollow fibres. The highly sensitive yarn material is processed as a yarn for weft insertion and handled with extreme care: with low yarn tension and deflection points, avoiding any relative speed and thus any stretching. The knitting thread fixes the hollow fibre, keeps it at a distance, prevents it from lying flat in a linear manner and thus guarantees optimum filtration conditions. The filter quality and flow rate of the warp knitted hollow fibre mats simply cannot be beaten – a performance that ensures maximum reliability and efficiency in filtration.

Saving costs and resources in construction

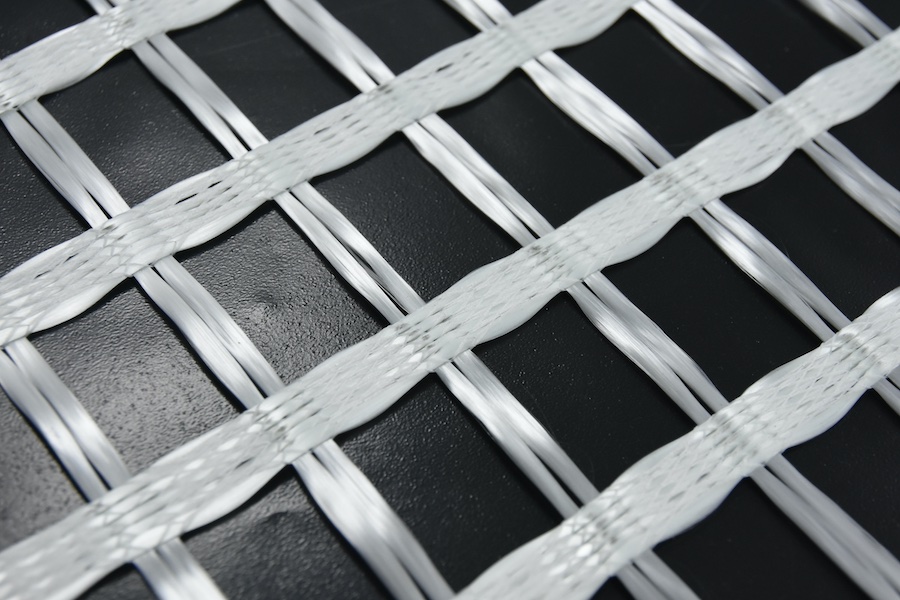

The construction industry requires more robust yet equally versatile solutions. Road construction has long relied on coarse, high-performance geogrids made of glass fibre material and other high-performance fibres, which are manufactured on warp knitting machines with weft insertion – including the WEFTTRONIC® II G – and used in a wide range of applications. In existing roads, they act as reinforcement grids to prevent cracking and rut formation and to distribute the load from traffic horizontally. When constructing new roadways, the power textiles reinforce the subsurface, separate its individual layers and provide filtration effects. In addition, in sloping terrain the high structural performance of warp knits made on weft insertion machines protects the surroundings from landslides. Unlike steel slope reinforcements, these textiles do not corrode and the textile solution can be easily installed in the landscape with minimum intervention.

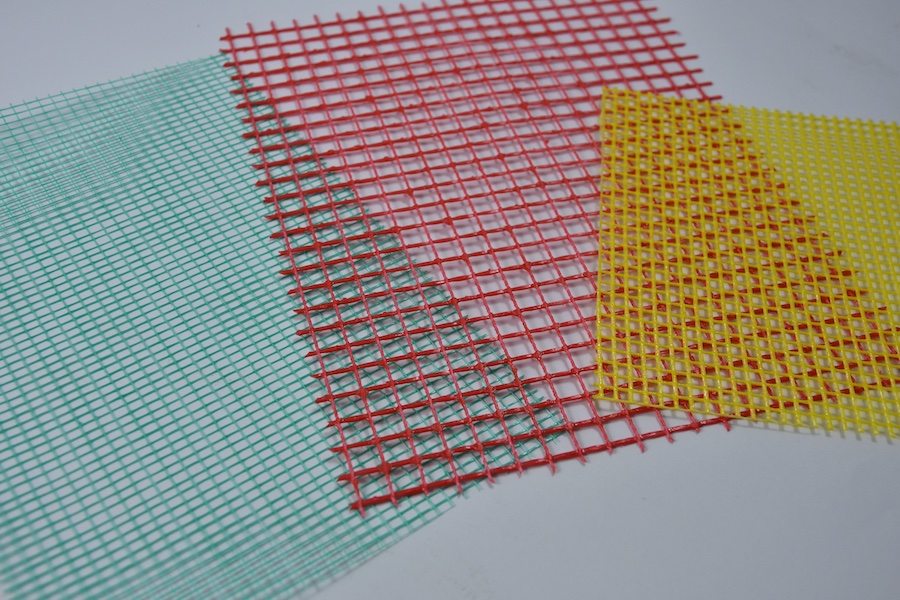

Textiles also offer new ways of thinking about the construction and renovation of buildings. Reinforcements made of non-crimp fabrics and warp knits made on weft insertion machines eliminate the need for steel reinforcement in concrete construction, thereby reducing the CO2 footprint and environmental impact of this industry. Warp knitted plaster grids prevent the emergence and spreading of cracks, distribute the force optimally and ensure a long-lasting facade cladding. They can be produced extremely efficiently and in the highest quality on the WEFT GRID ECO. This warp knitting machine with weft insertion protects the functional but brittle fibre material, usually glass, produces very little yarn waste and is highly efficient. Its output of mesh fabric is up to 12 times higher than that of weaving machines for dense variants and up to 17 times higher for open structures.

When it comes to cost-effective roofing solutions, warp knitted coating carriers from WEFTTRONIC® II RS are right on target. The textiles produced by this reliable, high-performance Raschel machine with weft insertion can be processed into flexible, stable material systems characterised by high weather resistance. They are UV-resistant and reflect the sun's rays, thereby reducing the energy required for cooling.