#Sustainability

Levi Strauss & Co. and Hohenstein collaborate

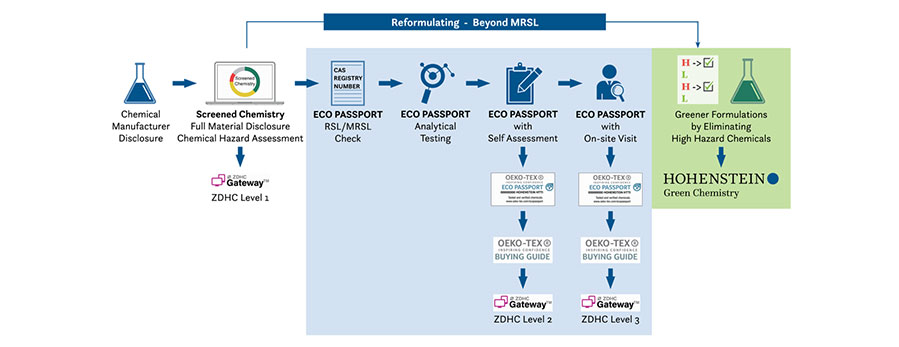

LS&Co. and Hohenstein both approach chemicals management from the perspective that safer inputs lead to safer outputs. Screened Chemistry, originated by LS&Co. as an open source program others can adopt, scrutinizes chemical formulations to prevent potentially hazardous compounds from entering the apparel supply chain and identify safer alternatives. By screening emerging chemistries that are not yet covered by Manufacturing Restricted Substances Lists (MRSLs), LS&Co. has created a more holistic approach to ensuring safe and responsible chemicals management.

ECO PASSPORT by OEKO-TEX® is an independent certification system for chemicals in the apparel, textile and leather industries. During a multi-stage process, ECO PASSPORT analyzes whether each individual ingredient in a chemical product meets international statutory requirements and is not harmful to human health. On-site inspections can validate claims that suppliers are using safer and better chemistry, manufactured according to industry best practices.

“Levi Strauss & Co. is committed to responsible chemicals management across our supply chain and our industry. This collaboration helps take our existing programs to the next level by establishing a new standard for responsible chemical stewardship that melds the hazard-based approach of Screened Chemistry with the robust testing and validation capabilities of Hohenstein,” said Michael Kobori, Levi Strauss & Co. VP of Sustainability.

“We believe that the collaboration between LS&Co. and Hohenstein is a significant step toward identifying and pulling better chemistry into apparel, footwear and textile supply chains,” said John Frazier, Senior Technical Director at Hohenstein.

“The coupling of Screened Chemistry, ECO PASSPORT by OEKO-TEX®, brand leadership and progressive chemical suppliers is a powerful signal of good things to come for chemicals management.”

The combined use of Screened Chemistry and ECO PASSPORT complements the recognized standards agreed upon by the Zero Discharge of Hazardous Chemicals (ZDHC) Roadmap to Zero initiative, an industry collaboration designed to drive the adoption of safer chemistry across the apparel supply chain. Through its testing and on-site verification, ECO PASSPORT will enable chemical suppliers to achieve higher levels of conformance with ZDHC. ECO PASSPORT’s certification results are published in the OEKO-TEX® Buying Guide, providing a credible third-party assessment of chemical supplier performance.

This partnership will enable LS&Co. to advance and better implement its existing chemicals management program and create a template that others in and beyond apparel can follow. The result is a program that goes beyond a risk management approach and provides a roadmap for companies to eliminate and prevent the introduction of chemical hazards in the supply chain.