#Sustainability

Textile Exchange reports global production of organic cotton increases 56 percent

Latest figures show that global production of organic cotton fiber reached 180,971 metric tons (MT) in 2017/2018 - the highest volume seen since 2009/2010 when the financial crisis led to a dramatic decline. Textile Exchange, the only organization to collect and report on global organic cotton production data, estimates that this growth is set to continue, with India, Tanzania, Turkey, Kyrgyzstan and China all having significant areas of cotton-growing land in transition to organic.

The number of facilities certified to voluntary organic standards is also on the rise, with facilities certified to the Global Organic Textile Standard and Textile Exchange’s Organic Content Standard growing by 15 and 16 percent respectively.

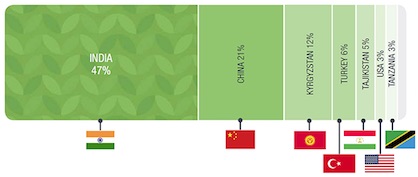

Cotton is grown organically in 19 countries around the world and the Organic Cotton Market Report reveals that 98 percent of the production stems from just 7 of these: India (47 percent), China (21 percent), Kyrgyzstan (12 percent), Tukey (6 percent), Tajikistan (5 percent), the United States (3 percent), and Tanzania (3 percent).

Organic cotton now makes up 0.7 percent of total cotton production globally. In 2017/2018, the fiber was planted on a total of 356,131 hectares (ha), with an additional 44,394 ha in transition to organic. Production was carried out by a total of 182,876 farmers, the majority of whom were smallholders growing organic cotton in rotation with other crops. An interesting trend, identified in India this reporting year, was that organic cotton farmers increased the proportion of certified land used to grow cotton (as opposed to other organic crops) from 45 to 70 percent, which contributes in part to the 44 percent growth seen in India’s production.

Farmer access to cotton seed that has not been genetically modified (GM) remains a huge obstacle for organic farmers, particularly in countries such as China and India where GM cotton dominates the cotton landscape. The report highlights some of the great progress being made in this area and includes an urgent call to action for added investment in non-GM seed programs, as well as for companies to develop their own organic cotton safeguarding programs.

With the rise in awareness of the climate emergency that our planet is facing, Textile Exchange sees organic cotton as a key component to the myriad of solutions that are urgently needed. Liesl Truscott, Director of European & Materials Strategy at Textile Exchange, said:

“Organic cotton, alongside other organic land-based fibers, must be part of the future. Organic cotton farmers, organizations, companies, and other supporters represented in this report provide a guiding light. We are proud to bring you our 2019 Organic Cotton Market Report and are committed to leveraging organic cotton as a market-driven solution to industry transformation and meeting the Global Goals.”

Textile Exchange’s Managing Director, La Rhea Pepper, also believes wholeheartedly in the importance of this fiber in driving change:

“Organic production of cotton is the tip of the spear that has been driving change within the sector. It establishes a direction of travel for all of us, starting with regenerative soil practices.”

The 2019 Organic Cotton Market Report provides a unique overview of global organic cotton production, focusing on the 2017/2018 harvest year but including both historical trends and forecasts at global, regional, and country levels. Also included are stakeholder maps identifying the key initiatives working hard to support organic cotton in each region, alongside latest updates from many of these programs and Q&As with industry insiders.

Download the full 2019 Organic Cotton Market Report

https://store.textileexchange.org/product/2019-organic-cotton-market-report/