#Spinning

Rieter Ring Spinning System powers Beste’s fully traceable supply chain

Beste and Rieter have signed an order to exclusively equip the newly founded spinning mill, FILUM S.R.L., in Bergamo, Italy, with the latest Rieter technology, including a complete ring spinning system. This is a pivotal step in the ITACO project, which encompasses every phase of cotton production – from the cultivation of organic cotton in southern Italy to spinning in Bergamo and garment manufacturing in the Prato region. Everything is done within a few hundred kilometers, providing unparalleled control over quality and sustainability, making Beste’s supply chain fully transparent.

From fiber preparation to winding, the new spinning mill will be exclusively equipped with the latest Rieter technology. With the fully electronic ring spinning machine G 38, equipped with the compacting device COMPACTapron, Beste produces combed compacted yarn that meets the highest standards required for its ITACO collection.

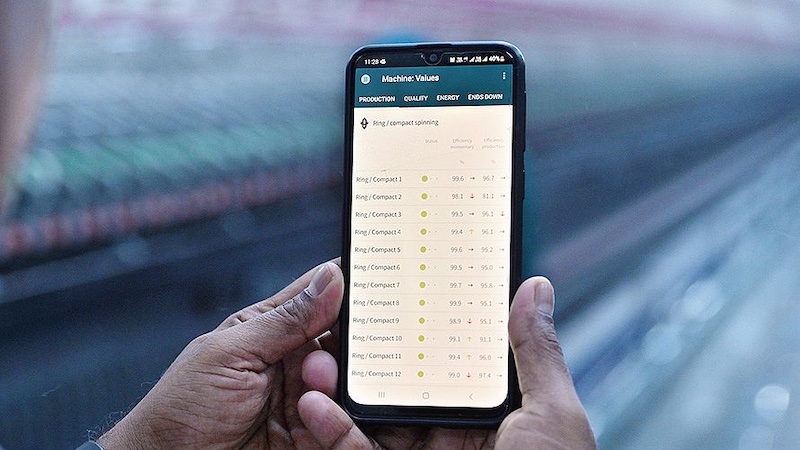

The all-in-one digital mill management system ESSENTIAL connects data throughout Beste’s new spinning mill, giving the company a comprehensive view of all relevant performance indicators from bale to package. The fully automated piecing robot ROBOspin ensures consistent performance of the ring spinning machines and minimizes personnel deployment. The fully automated roving bobbin transport system SERVOtrail Direct further reduces personnel requirements as no manual bobbin transport is needed.

"We engage with partners who share our philosophy and standards. Rieter machines meet our demand for the highest quality and enable us to produce yarns for our garments that embody the design and quality hallmarks of ITACO, our unique, fully traceable Italian cotton project", says Giovanni Santi, CEO of Beste.

Roger Albrecht, Head of the Rieter Business Group Machines & Systems, says: "We are proud that Beste has chosen our technology to accelerate their growth momentum. Our ring spinning system perfectly fits into this complete Italian production chain, supporting the ITACO project’s vision of high-quality, sustainable garments."

ITACO (Italian Cotton) is a groundbreaking initiative by Beste, aimed at creating a fully traceable and made in Italy supply chain for 100% organic Italian cotton. From seed to garment, ITACO covers all production stages within a few hundred kilometers in Italy, emphasizing quality, transparency, and local regrowth.