#Spinning

Pre-Cleaner CL-X demonstrates excellent performance after launch

Voices from the market are enthusiastic about the new pre-cleaner: “Since the delivery of our CL-X in May, we have been very satisfied with its cleaning efficiency. We also see a big advantage in its usability – it is easy to handle even for employees with less experience which is a decisive factor in times of staff shortage and high staff costs. Automated processes simplify the handling immensely”, says this customer from China, for example. He is processing 100-percent Xingjiang machine pick-up cotton which usually has a comparatively high trash content.

The CL-X reliably pre-cleans this raw material and thus allows for the production of a high quality carded ring yarn Ne 32. “Against the background of rising costs for raw material, energy and personnel in China, the CL-X proved to be the right investment” is the customer’s conclusion. Harald Schoepp, General Manager Trützschler Textile Machinery China adds: “The CL-X promises great potential in our market. We are pleased about the strong demand for this machine. Our customers are convinced by its efficiency and productivity. In many cases the CL-X can replace two pre-cleaners. This leads to space, time and cost savings.”

In other booming textile markets, such as Turkey, the CL-X is also gaining recognition rapidly.

“The CL-X has taken our blowroom to a whole new level: It reliably and gently removes coarse contaminants like seeds and stalks as well as small impurities at the same time with minimum loss of good fibers. Thus, we can meet the requirements of a high-quality end-product even better” says Mehmet Yilmaz, Business Manager at the company Biska from Turkey. Biska, which is one of the leading yarn manufacturers in Turkey, is mainly committed to the manufacture of cotton and produces high-quality carded, combed, compact and slub yarns between Ne 6/1 to 100/1. In the customer’s state-of-the-art spinning mill in Gaziantep, a total of four Trützschler blowroom lines, 42 cards and 22 draw frames manufacture 90 tons of cotton per day.

https://www.youtube.com/watch?v=HCO4npmf1hA

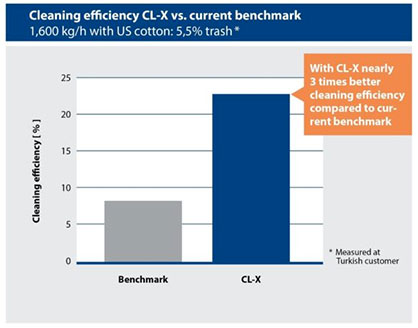

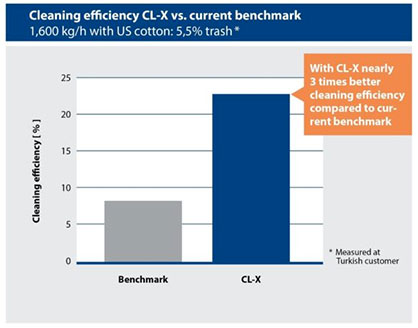

Biska and Trützschler started their long and successful partnership in the 1990s. As Trützschler solutions have never disappointed the customer, Mr. Yilmaz was pleased to have the first pre-cleaner CL-X installation worldwide. And he did not regret it – the results at Biska proved a three-times better cleaning efficiency compared with the current benchmark:

Another important motivation for the customer to introduce the CL-X was the promise of drastic energy savings. “When I started in this business, energy and personnel costs were about at the same level”, he says. “But by now energy costs increased much more”, explains Mehmet Yilmaz. “To save energy helps us to stay competitive – and to do something for the environment.” Comparisons with the current benchmark in combed-cotton-yarn applications showed that the CL-X saved up to 30 % energy:

Christoph Weber, Managing Director Trützschler Spinning Turkey, sums up:

“The extremely positive feedback from the market confirms that we have once again taken an important step towards future-oriented innovation with the CL-X. We have broken all previous order records in Turkey and are happy to provide our customers with the best solutions and services steadily.