#Spinning

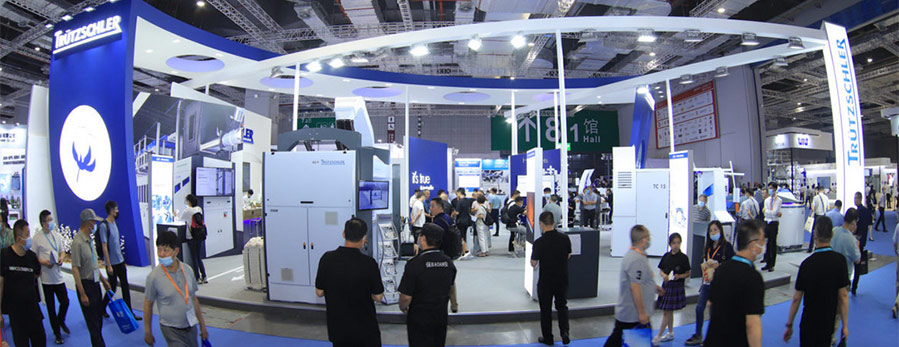

Trützschler highlights at ITMA Asia & CITME 2021

Besides technologies for producing biodegradable webs from renewable raw materials, comprehensive services, high-performance clothings for cards and more, the Trützschler Group presented new innovations to the global market for the first time:

“We are very proud to have introduced our new 1.28-meter carding machine TC 15 as well as the latest pre-cleaner CL-X at the Trützschler booth. Both machines promise to set benchmarks in the market.”, says Yu Zhenzhen, Marketing Manager at Trützschler Textile Machinery Shanghai (TTMS).

Another highlight was the celebration of the 8000th card delivered in China by TTMS. Fur this purpose, Ms. Yang Si, the second management generation of the customer Hubei Shufeng Textile Co. Ltd., where the 8000th card was installed, was invited to the booth to receive an award and a T-Winder. Further, Mr. Harald Schoepp, General Manager TTMS, held a speech on 20 years of Trützschler history in China and gave insights into the different card models delivered to the Chinese market.

Yu Zhenzhen sums up: ” We are very happy that this year’s exhibiton took place. A big THANK YOU to all the people who took the opportunity to visit us and to everybody who has contributed to making the ITMA Asia + CITME 2021 a great success.”