#Spinning

A family excursion: The MO40 system at Domotex Asia

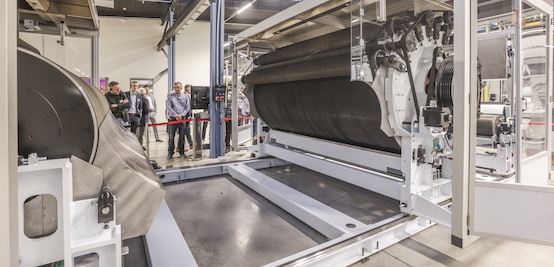

On the one hand, the extrusion system for BCF carpet yarns, which forms the basis for the machine, is tailored to meet the increasing demand for high-count carpet yarns for silky soft, velvety carpets and, at the same time, the design is ready to meet the needs of the large market for standard carpet yarns.

The production of high-count yarns is challenging as only wafer-thin individual fibres with the smallest diameter achieve the desired effect. The MO40-E puts efficient and convenient production of such fibres within reach. The maximum number of individual filaments increases by 50 % in comparison with the MO40-C – up to 500 to 750.

More individual filaments in a BCF yarn require more nozzles in the spinning package and as a result a wider spinning beam. High-quality yarns are only produced if the hot, formable filaments are cooled evenly after spinning. In order to achieve the appropriate circulation of process air, more space is also required in the quenching system. The partition of the MO40-E increases to 2,500 mm.

Given that high-count yarns are a niche product, the MO40-E is also engineered for the production of standard yarns with 3 dpf or more. In these cases, an MO40-C standard spinning package is used in the spinning beams with the help of adapters.

The increased flexibility – the operating window ranges from 500 to 7,000 dtex yarns – has its price when it comes to space requirement: Whilst the compact version MO40-C occupies a space of 2,000 x 2,000 mm, the space requirement of the MO40-E increases to 2,500 x 2,000 mm. Despite the constructional adjustments the dwell time of the melt remains very short, guaranteeing a consistently high product quality.