#Spinning

From waste to high-quality yarn

Contributing to the sustainable use of cotton with IDF 2

Using your own waste - a clever concept

One example of a successful sustainability concept is Bakan Tex in Uzbekistan. The company was founded in Tashkent in 2017 after the government decided to promote the entire value chain around the domestic textile sector.

Bakan Tex produces first-class combed ring yarn. In the process, the so-called comber noil, which contains short fibres and neps that are undesirable in high quality combed ring yarn, is combed out at the combers. As the fibres have already passed through the blow room and over the cards, it is a high-quality “waste”.

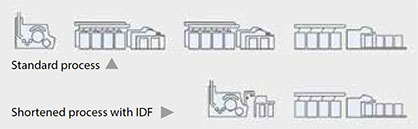

Comber noil is a recyclable raw material which is used, for instance, in banknotes or hygiene products. It can also be spun into excellent rotor yarns. This is made possible by shortening the process through the use of Integrated Draw Frames (IDF).

The IDF allows to process significantly shorter fiber length into a good yarn. The yarn is of excellent quality even if 100 % comber noil has been processed. Until now, this has not been possible without the shortened process.

Interview with FT Textile

Bakan Tex already uses this great potential. The subsidiary FT Textile, founded in 2019 – a rotor spinning mill which processes the noils of Bakan Tex – is operated by 250 employees. 22 IDF 2 produce the feed for 8640 rotors. Furthermore, the company invested in additional IDF machines and a recycling plant to process blow room and carding waste with the short preparation process. We spoke to Mr. Sekar Rajam (CEO of FT Textile), Mr. Jaya Prakash (Quality Production Manager) and Mr. Abdukayum Saidov (Director) about the advantages of the shortened process with IDF.

What made you decide to process your own noils with IDF2? What convinced you of this concept?

FT Textile At FT Textile we rely on OE spinning. We use 100 % raw cotton, but also cotton mix with waste (comber noil). This process allows excellent processing of short fibres (fibre length 20.6 mm) into yarn.

What are the main advantages of the shortened process for your spinning mill? Does it open up savings potentials for you?

FT Textile This process is particularly suitable for us, since we can use short waste fibres produced during combing, in addition to so-called virgin cotton, without any problem. This not only saves raw materials, but also space, energy and personnel.

How much yarn do you already produce with the shortened process? And how are your future plans in this respect?

FT Textile So far we have produced an average of 450 tons per card. We produce yarn from Ne 10 to 36. In the near future, we expect to produce at least 1,000 tons of yarn per card with consistent quality.

What blending ratio do you use? And how much waste and raw cotton do you blend?

FT Textile We produce with three blending ratios: The first blend consists of 100 % raw cotton, blend 2 of 80 % cotton and 20 % waste. Blend 3 contains only noils.

How do you assess the yarn quality? What do your customers say?

FT Textile Excellent! We are extremely satisfied with the quality. We have not yet received any major complaints from our customers.

For which end products are the yarns produced with the shortened process (IDF2) used?

FT Textile Our customers mainly come from the knitwear and woven fabric sector.

In your opinion, what are the ecological advantages of this process?

FT Textile The most important advantages for us are the significant energy savings and the reduced space requirement. Also important for us is the fact that we need less personnel due to the simplified can transport.

How do you assess the future significance of the shortened process?

FT Textile We are convinced that the shortened process will continue to be important for us.

The shortened process: a model for a more sustainable future

Our practical example illustrates the particular advantages of the shortened process with IDF 2. Thus, the current challenges of saving raw materials and energy are met by us and our customers. In addition to FT Textile, the shortened spinning preparation process is already used by other customers to process their own comber waste into high-quality rotor yarns.

Cotton and environment

The demand for textiles and thus for cotton products is growing steadily due to population growth and increasing per capita consumption as a result of economic prosperity.

Cotton is cultivated worldwide on an area as large as Germany. However, cotton production cannot be increased at will, as agricultural areas are limited.

In addition, the plants require warm climatic conditions and an extremely large amount of irrigation. Furthermore, they are treated with pesticides and insecticides and thereby account for ten percent of global pesticide and fertilizer consumption.

Cotton is therefore a highly sought-after but also controversial raw material. That is precisely why efficient use is necessary. This circumstance is countered on the one hand by adding synthetic fibres to cotton, and on the other hand by sustainable methods of utilising the raw material.

Since 2019, both the production and the processing of sustainable cotton have been supported by the Federal Ministry for Economic Cooperation in the countries of Uzbekistan, Cameroon, Burkina Faso and India. Existing platforms and initiatives worldwide are integrated to increase sustainability in the cotton industry. Among other things, training courses for farmers on more sustainable cultivation methods are offered within this framework.