#Spinning

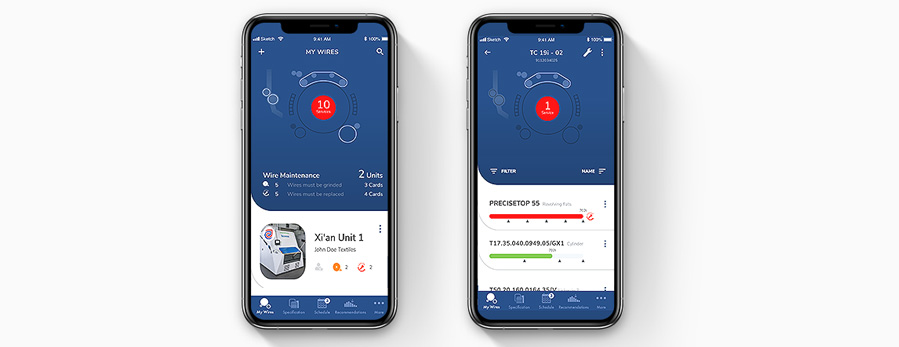

My Wires – The smart way to manage card clothings

Stop counting days and digitize in minutes

When it comes to track the wearing of their carding wires, many mills still rely on pen and paper. Employees manually note down every day how many days each carding machine has run between services. This tracking method is imprecise, means a lot of work and no one can access it in real time.

How to simplify wire management? It’s Easy! With the My Wires app.

https://www.youtube.com/watch?v=U3iptx2xgcU

How does it work?

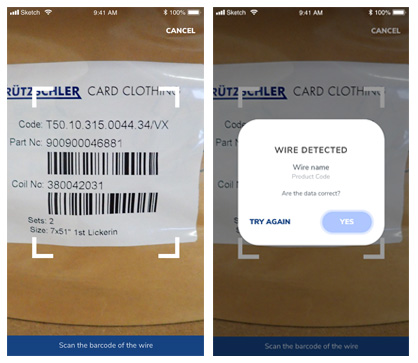

My Wires tracks the wearing automatically and according to the customers’ needs. For all cards and wires, independent of manufacturers. By scanning new wires, an automatic tracking will start. Users can opt for push notifications to remind them of important upcoming events, like when a wire must be replaced. Now it is possible to plan the maintenance for the next month and generate order lists.

Need a starting point for superb quality?

Over the years Truetzschler has developed its know how on the interaction between cards and their clothings. My Wires has the maintenance recommendations of the premium partner Truetzschler Card Clothing already included. In case customers worked out their personal best results, they can set the recommendations to their specific needs. Push Notifications will notify them of any upcoming services.

Benefits of your Truetzschler account

The owners of a free My Identity account (https://myidentity.truetzschler.com/) can now combine their benefits. Initially, My Identity users could access the web shop and access the spare parts list of their machinery as they were commissioned. With My Wires, they can use the same login and don’t have to remember another password. Even better, all their projects, cards and wires are available as Easy Setup in My Wires, allowing them to digitize their complete wire management process in a few minutes.

Easy ordering

If the customer needs to plan the upcoming orders of the next month or year, My Wires will provide him with an exportable schedule already listing the correct article numbers*. This allows a better overview and a faster internal purchasing process.

Cloud-based solution

The digital offers are cloud-based and extremely secure. Truetzschler relies exclusively on the highest security standards.