#Spinning

The portal solution for higher productivity and increased quality

First customer feedback

The Indian company Polytex was equipped with the first portal bale opener in India prior to ITMA in Barcelona. Within less than one week the entire installation and start-up was completed. By positioning the BO-P with a working width of 2,9 metres and a length of 60 metres close to a wall it was possible to save space.

For the deputy general manager K. Sundara Rajan it was important to invest in the currently most secure bale opener on the market: “A comprehensive concept to ensure the safety of the employees is of great significance for the company. The combination of the high working width and the lower overall width was another essential argument for the purchase”. After about 7 months of experience with the BO-P the customer highlights also the low maintenance and the quiet operation.

Johannes Bossmann, design engineer, about the way from the idea to the finished product: “When the concept of the portal bale opener was presented at Truetzschler for the first time, the benefits for our customers were clear to see. At that time the BO-P was only an idea without any proof from the market and with many technical and technological challenges ahead. Truetzschler had the knowledge, experience and confidence to put this idea into reality. It’s a big joy to see that the BO-P is well received and that it performs the way we promised it to our customers.”

From a bale plucker to the portal bale opener

The Truetzschler blow room was born in the beginning of the 20th century. In 1902 Truetzschler started to expand its product range and began to build cleaning and dust removal systems for cotton processing. The first automatic bale work-off in form of a “bale plucker” was introduced in 1963. 16 years later, in 1979, the BLENDOMAT, which worked according to the “bale milling” principle, was created. Over the years the BLENDOMAT principle has been adopted by all machine builders worldwide. 2019 Truetzschler presented the next generation at the ITMA in Barcelona. The Portal Bale Opener BO-P sets new standards in quality and economy.

Better blending from the start

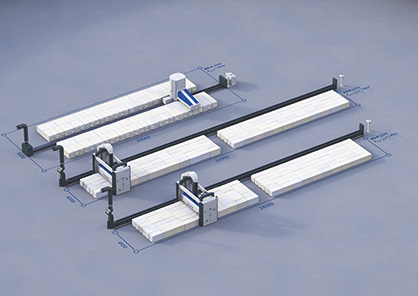

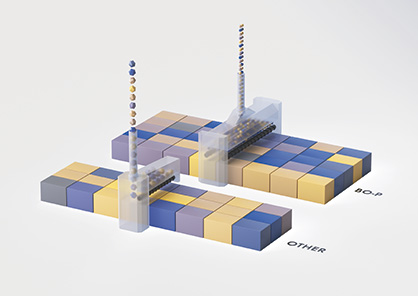

The new and unique portal concept makes the large working width possible in the first place. With a 2,9 m or 3,5 m width and a bale lay-down area of up to 75 m length, the Portal Bale Opener BO-P offers flexible bale placement. Because two opening rolls work in parallel, tufts from 5 to 14 bales are processed simultaneously. This lays the foundation for homogeneous blending in the blow room.

Increased opening and higher performance

The two longwork-off rolls have nearly twice as many teeth, newly arranged. This results in a fiber-friendly work-off and a uniform, homogeneous surface appearance. Due to the large working width and the simultaneous use of two opening rolls, small tufts are already produced during the first process in the spinning mill. This is impossible for systems with only one roll and a smaller working width. The new conditions allow productions of up 3.000 kg per hour.

Less space requirement and better accessibility

The bale work-off couldn’t be more compact and space-saving. With a working width of 3.5 m, up to 460 bales can be combined to a bale lay-down. An intelligent workplace protection on the BO-P does not require any space-consuming safety areas. To make optimal use of the space, the BO-P can also be positioned close to the wall with free access to the bale lay-down area. In addition, the new bale lay-down on only one side considerably simplifies the bale logistics in the spinning mill. The long bale lay-down area can be flexibly used. The areas can have different lengths. This, for instance, can be beneficial to span an unattended night shift or weekend.

Simple and easy to operate

The remote display T-LED clearly indicates the operating status also at a larger distance and eliminates unnecessary walking for the operator. In case of malfunctions and prior to machine start-up, clear visual warnings are issued.