#Spinning

The long view for ring spinners

USTER® SENTINEL is the key to optimized yarn production

Since normal walking pace is about 4,000 meters per hour, an operative would typically need about one minute to arrive at an end-break at the last spindle on the frame. So, the spindle could be easily back in action again within two minutes – assuming, of course, that the operative knows exactly where to go…

Ring spinning optimization

It’s a fact that high-performance potential and enormous ring-spinning machine capacity are worthless if spindles are at a standstill because of end-breaks. USTER® SENTINEL is the answer: its bobbin build-up report is the key to optimized yarn production. The system’s unmatched detection of end-breaks provides the basic platform. USTER® SENTINEL guides machine operators straight to spindle breaks, through clear and simple indications by red light dots.

End-break levels are a key indicator of ring spinning performance, so USTER® SENTINEL’s intuitive bobbin build-up report includes every parameter influencing end-breaks. Clear visuals point to exact reasons for breaks, making optimization easy. Spinners can then make the required improvements, focused on ambient conditions, wear of mechanical parts and machine speed.

With real-time performance information, USTER® SENTINEL offers mills the data to raise yarn production efficiency to the next level. Its easy-to-use software gives a rapid, tailor-made overview of machine performance, highlighting exactly the most relevant production and laboratory data. An attractive feature is the real-time information on energy consumption. Only with real-time data can mills take the opportunity of immediate optimization.

The real difference

Combining this total control of end-breaks with USTER® ROVING STOP leverages the efficiency of yarn production. The instant stop of roving feed at an end-break reduces waste significantly and makes raw material usage more cost-effective. Calculations show that 70% less pneumafil waste equates to a saving of nearly 1% in raw material, based on current spinning conditions. Obviously, this makes for a shorter investment payback too.

Reduced levels of waste and uncontrolled fiber fluff prevent quality issues around neighboring spindles and along the entire machine. Better operating conditions and reduced repair times result in higher yield and fewer quality issues. Badly-performing spindles are reliably identified and other issues which often impair the spinning process – such as idle, rogue and uniquely off-quality spindles, as well as spindle slip – are all monitored for fast response.

The summit of production efficiency

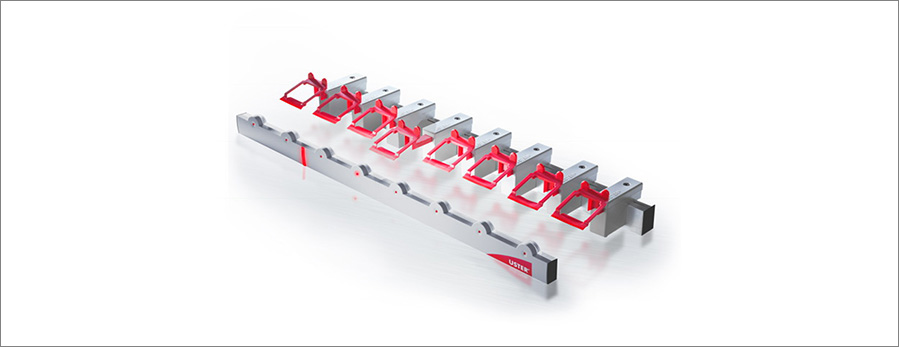

Human limitations on eyesight and speed are irrelevant with USTER® SENTINEL in place – and even the multiple number of spindles in a ringframe makes no difference. Downtime is kept at the lowest possible level – an unbeatable achievement also thanks to the unique design of USTER’s ring spinning optimization system. The streamlined and uncluttered profile of the USTER® ROVING STOP is geared to optimum machine performance. The distinct compact shape ensures easy and effortless piecing access, since its sensors don’t need to be positioned too close to the ring, which also saves time and speeds up responses.

For the ultimate in quality optimization, USTER® SENTINEL is ready for connection to the Total Testing Center of USTER® TESTER 6. Here, data from all spinning processes is integrated and interpreted, providing comprehensive guidance for users to maximize both efficiency and quality.