#Spinning

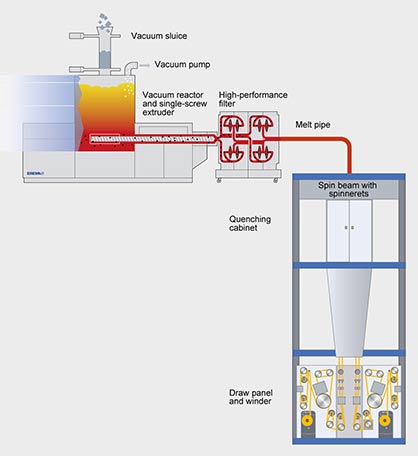

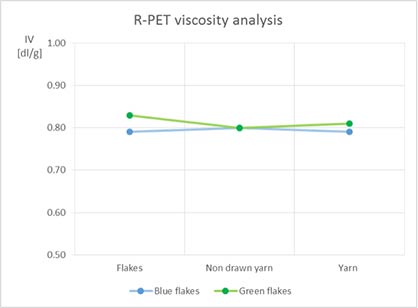

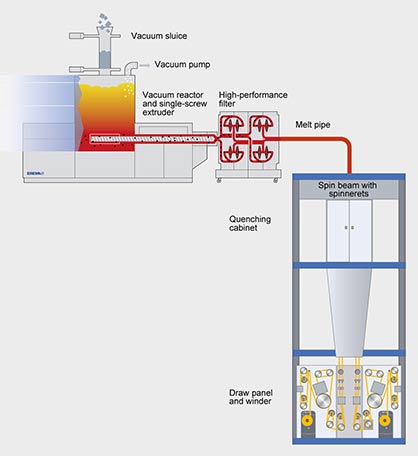

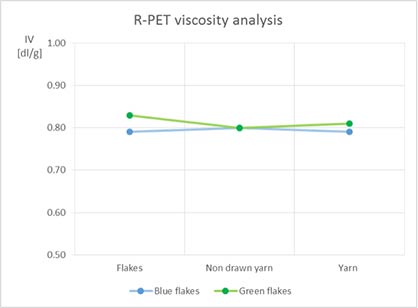

A new technology from Trützschler Switzerland AG and EREMA for production of BCF yarn from recycled PET (R-PET)

In today’s textile industry, excellence is not achieved by chance – it’s the result of deliberate decisions, technical expertise, and the courage to go beyond conventional paths. The Turkish company Zirve Tekstil has done just that: by combining the best technologies from Trützschler, Toyota and Murata, they’ve created a production setup that delivers outstanding yarn quality – recognized worldwide.

Pakistan’s textile industry, especially its spinning sector, is the backbone of the national economy and a vibrant hub of innovation. Today’s spinning mills face growing demands for efficiency, quality, and sustainability. From the serene northern valleys to the vibrant port city of Karachi in the south, mills like Suraj Cotton Mills, Liberty, and Nishat Chunian are turning to advanced solutions.

In virtually all spinning mills, transporting sliver cans is still done manually. Rising labor costs, lack of operators and increasing quality requirements make this a growing challenge. With T-CAN, Trützschler introduces a practical solution: a fully automated can transport system that will be presented live at ITMA ASIA 2025 in Singapore.

What if the future of cotton cleaning was already here – setting a new standard for cleaning efficiency, productivity and energy savings? That future has a name: CL-X. Since its market launch in 2022, the Pre-Cleaner CL-X has become a true bestseller, proving its value in several hundred customer applications worldwide. Now, new results from Türkiye demonstrate again how the Pre-Cleaner CL-X outperforms the competition.

Rieter successfully completed the acquisition of Barmag on February 2, 2026, and reached an important milestone in the company’s repositioning. Barmag will be integrated into the Rieter Group as the “Man-Made Fiber” Division. With this strategically transformative acquisition, Rieter is expanding its core business beyond the short-staple fiber business in a targeted way. This positions Rieter as the global market leader along the entire value chain for natural and man-made fibers. In addition, as a complete systems supplier, Rieter is further strengthening its technological leadership in the areas of automation and digitization.

Producing consistent yarn quality is an everyday challenge – and a very difficult one. Detailed knowledge and understanding of the fiber raw material is absolutely critical to achieving the best possible quality in the yarn. To help spinners, Uster experts have put together guidelines for avoiding yarn irregularity claims, in a special edition of the Uster News Bulletin.

Developed and manufactured by Mesdan, Italy, the Loop knotter type 093E is a special version of the well-known Loop knotter, specifically designed to join hygiene-grade spandex yarns used in the personal care industry.

Global political and economic developments have been leading to rising raw material and energy costs for some time. The textile machinery industry is also affected by this trend. Rieter machines and components consist to a large extent of steel, copper, aluminum and electronics. These materials in particular have seen higher demand and higher prices in recent months.

With the European Commission’s decision to provisionally apply the EU–Mercosur Interim Trade Agreement, a process spanning more than 25 years now moves decisively into its implementation phase.

Selenis, a global leader in high-performance specialty polyesters and part of the IMG Group, has announced a transformational expansion of its industrial headquarters in Portalegre, Portugal. This strategic investment is set to double the site’s production capacity by the third quarter of 2027, significantly accelerating the industrial scale-up of bio-based, medical-grade, and circular co-polyesters.

Independent laboratory testing has confirmed that Milliken fabrics used in the manufacturing of firefighter turnout gear contain no detectable PFAS, based on third-party analysis conducted by Forever Analytical, an independent laboratory specializing in screening products and environmental samples for the presence of per- and polyfluoroalkyl substances (PFAS).

Following the conclusion of Heimtextil last month, the flagship fair in Messe Frankfurt’s global home and contract textiles portfolio, Intertextile Shanghai Home Textiles – Autumn Edition will return 18 – 20 August 2026 at the National Exhibition and Convention Center (Shanghai). Building on the momentum generated in Frankfurt, the Shanghai fair will reinforce its position as the foremost home and contract textile platform in Asia – successfully bridging the gap between East and West, and connecting global product trends, supply-chain shifts, and buyer demand in one marketplace.