#Software

3D technology for effective product development – bonprix relies on 3D Vidya by Assyst

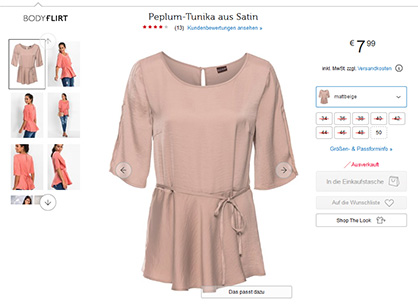

The vertically integrated fashion supplier bonprix stays in constant touch with the latest trends, offering its female customers a full range of styles and sizes for all occasions. However, the route from the idea to the finished product is often time-consuming and resource-intensive, so bonprix is introducing 3D Vidya by Assyst to accelerate collection development and reduce the number of physical patterns at the same time. The 3D simulation software makes it possible to visualize garments digitally and to display them as three-dimensional patterns on a screen. This means that bonprix designers can see how a garment works, how it drapes and how the sizing & fitting can be optimized – without the need for a physical pattern. Fabrics and colors can be changed lightning-fast and different variants can be easily tried out with just a few clicks. “What’s special about 3D product simulation is that you can see what you get before it’s produced. This saves a lot of resources, time and costs and gives us much more flexibility in product development,” says Stefanie Sumfleth, Head of Quality Management, Corporate Responsibility & Digital Product Development at bonprix. “We can react even faster and more efficiently to trends and increase the quality of our products – and that makes our customers even more satisfied. With Assyst and its 3D Vidya tool, we have an ideal partner at our side for this project.”

The company will initially introduce 3D Vidya for the product development of shirts, nightwear, blouses and shirts. “We’re actively supporting the bonprix team during the introduction and gradually expanding the range to other product groups,” says Dr. Andreas Seidl, CEO of Assyst. “Our goal with 3D Vidya is to significantly reduce the number of physical patterns. Thanks to 3D, many complex changes to patterns can be avoided because the garment can be checked for different requirements at an early stage. Ideally, only one single sample will be created before production starts.”

The elimination of physical patterns not only makes the collection development process faster and more efficient, fewer materials are also processed in the course of product development – and in the case of samples produced abroad, frequent long journeys to Germany for coordination with product managers are eliminated. The use of 3D Vidya therefore has a positive impact on the ecological balance – and that’s an important plus for the fashion company bonprix, since the CR strategy of the company stipulates the continuous checking and developing of the entire value chain for sustainable aspects.