#Software

Assyst now has a strong cooperation partner in SACO

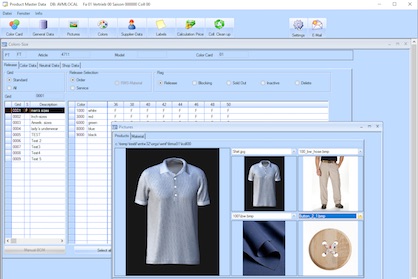

Digitalization needs highly specialized software solutions – and two highly specialized software providers for the sewing industry will now complement each other thanks to the new cooperation between Assyst and SACO. Assyst will contribute extensive expertise in the use of CAD, PLM and 3D solutions, particularly for the product development process, while SACO will focus on state-of-the-art ERP and PDM systems. “The integration of management systems into the product development process, in particular the interaction of PLM and ERP, is of enormous importance for successful digitalization,” says Dr. Andreas Seidl, Assyst CEO. “We look forward to working with SACO and providing the best tools for the digitalization of the fashion industry.”

Cooperation in sales

As part of the cooperation, SACO will take over the maintenance and support of the BOS and SAM products and – backed by its many years of know-how – will provide the best possible support for Assyst customers. In return, Assyst will distribute SACO’s APPone products in addition to its own developments. The integration of ERP-BOS with its own products PLM.GoLive and Cad. Assyst will continue to be an important focus of the Assyst strategy. Assyst is the only company in the apparel industry to promote the integration of all products along the product development process chain with the aim of securing maximum added value for its customers. Assyst will also focus on the further development of its solutions on integration with the 3D simulation software Vidya, which fully supports the digitalization process for design, development and distribution.