#Research & Development

Toray develops Hollow Fiber Membrane Module that can slash CO2 emissions in food and beverage and biotechnology processes

This module can save energy and contribute to carbon neutrality by attaining CO2 emissions that are more than 80% lower than those from the food production sector’s conventional thermal concentration processes. The company will accelerate development, with a view to full-fledged mass production, and will cultivate an array of applications.

Hollow fiber membranes have become one of the mainstream in liquid filtration due to their excellent separation, high membrane integration, reduced footprint, and superb area utilization efficiency. Toray’s exiting hollow fiber membranes are used widely in water treatment. This is because its polyvinylidene fluoride ultrafiltration hollow fiber membrane technology delivers exceptional durability and separability.

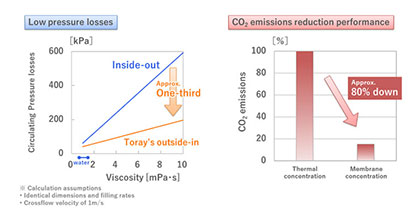

Toray leveraged the high-strength hollow fiber membrane technology cultivated in water treatment to develop the new module, which employs an outside-in type crossflow filtration design. Crossflow filtration is a common technique, through which feed passes parallel to membrane surface and prevents turbidity from accumulating. Pressure losses from this design are just one-third those of inside-out type that food companies normally use. It is thus possible to filter and concentrate highly turbid or viscous liquids, which is challenging with regular membranes.

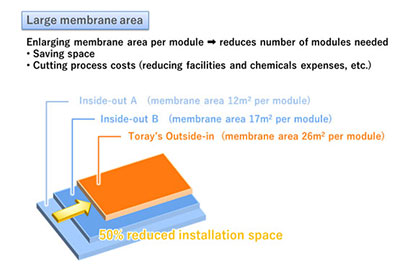

Other benefits of Toray’s new module are that it features large membrane area technology which reduces the number of modules needed, halving space requirements and potentially lowering cleaning and equipment costs by more than 20%.

The module performs well in steam (125°C) and hot water (90°C) environments to enable thermal sterilization and high temperature filtration. Filtration testing of a high turbidity microbial culture solution with the new module demonstrated stable, long-term filtration, with steam sterilization preventing bacterial contamination for more than 20 days.

Toray will build collaborative ties with engineering companies in Japan and abroad to develop an array of uses. They include high-viscosity, and high-turbidity raw water applications that have to date employed solid-liquid separation technologies such as diatomaceous earth filtration or centrifugation. They also encompass food manufacturing and bio production processes in which production lines require thermal sterilization.

Based on the corporate philosophy, Toray will contribute to the development of society and technology by continuing to produce high-performance, cutting-edge materials.

https://go.mktg.toray/t012-WC-20211119-1965-01-DownloadPage.html