#Research & Development

Resource dog fur: Finest animal hair fibers for sustainable and ethical fashion

Chiengora® is what they call the cashmere-like yarn - "Chien", French for "dog", and "gora" in reference to the fine angora that originally comes from rabbits. The yarn has the advantage over cashmere in that the raw material does not have to be flown in from Mongolia and the animals are not bred and kept for wool production. The raw material for the yarn is produced incidentally during daily animal care, especially when the animals shed their winter coats in the spring. Thus, the use of Chiengora® not only conserves resources, but also serves animal welfare.

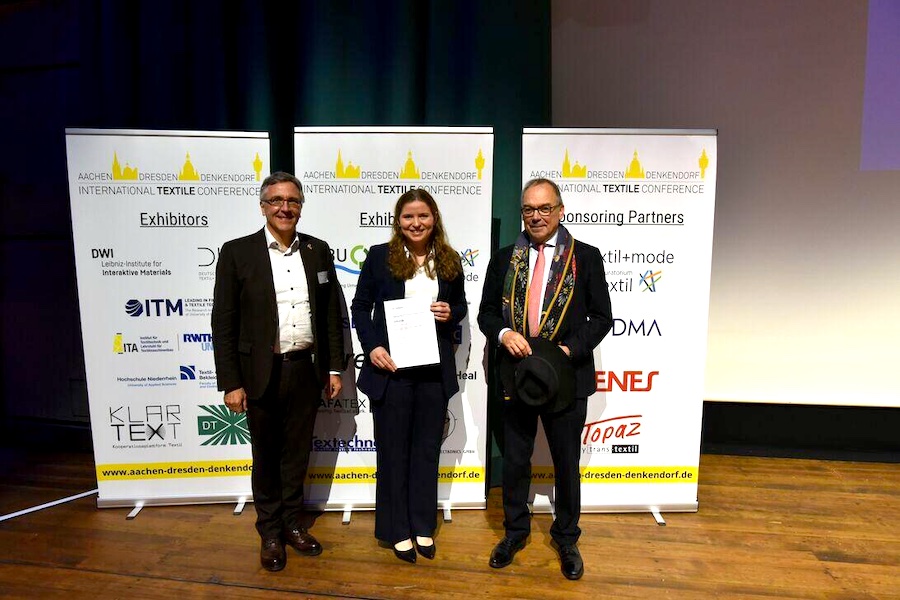

The founding team consists of Ann Cathrin Schönrock (31) from Berlin and Franziska Uhl (25) from Reutlingen. As a trained fashion and knitwear designer with high demands on quality, ethics and sustainability, Ann Cathrin Schönrock started collecting the undercoat from her own dog, from dogs of acquaintances and friends, but also from groomers and breeders back in 2017. After initial feasibility studies, Franziska Uhl from the Faculty of Textile & Design at Reutlingen University joined the team. As part of her bachelor's thesis, she researched which dog hairs are particularly suitable for yarn development. At the DITF, together with Volkan Ünal and Waltraud Abele, she tested her theses on industrial-scale machines and optimized the production processes - from wool fiber flocks to finished wool yarn.

The potential is great. There are more than 10.4 million dogs in Germany alone. Although not all dog breeds have suitable undercoat, so far more than 1,000 tons of it end up in the garbage every year throughout Europe. Schönrock and Uhl have set up a decentralized collector network. Anyone can participate, collect the undercoat of their four-legged friend and send it to Reutlingen. The project is supported by the state EXIST start-up grant and an investment from the textile industry. The entrepreneur Anna Yona from Wildling invests in "Yarnsustain".