#Research & Development

ITA: High-performance warp knitting machine "BIAXTRONIC CO" from Karl Mayer facilitates production of innovative semi-finished fibre products

With the procurement of the high-performance warp knitting machine with course-oriented weft-insertion system, further development and production of reinforcement structures for concrete matrices are aspired. Furthermore, the new machine will also be used for the development of functional samples/prototypes in other application fields such as:

- Production of hybrid knitted fabric structures over a non-woven substrate

- Manufacture of unidirectional (UD) fabrics for fibre-reinforced plastics and plain knitted fabrics for thermal textiles in the mobility sector

- Reinforcement of wound dressings in the medical textiles sector.

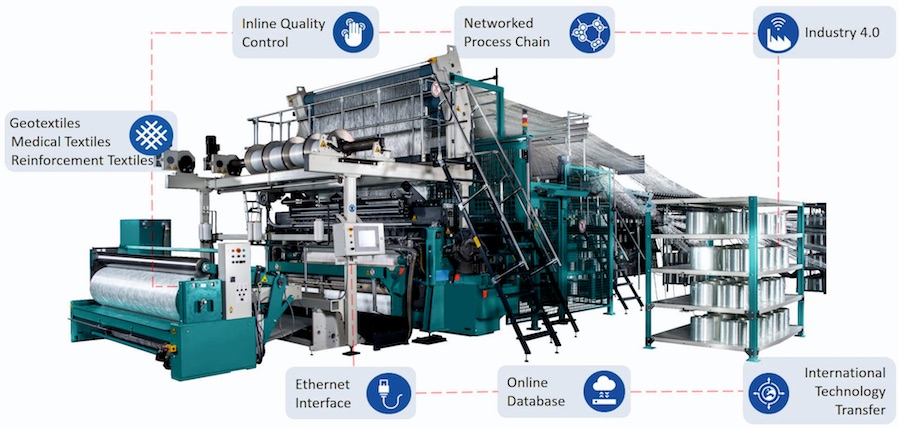

The new machine platform comes with new features which open up new research avenues for ITA and its research partners (as depicted in figure "BIAXTRONIC CO opens new research opportunities").

The possibility to feed in base substrate will allow ITA to fundamentally research applications in the field of geotextiles. The installed Karl Mayer Command System “KAMCOS” includes an ethernet interface for integration into an existing network, which fulfils the requirements for research topics in the field of Industry 4.0, inline quality control, sociology, networking of the process chain etc. The newly developed electronic guide bar control system and the possibility to vary process parameter inline will improve the product quality substantially and help in producing locally adapted tailored textiles.

ITA thrives on the development of new innovative technologies and products, which mainly result from bilateral research projects between industry and universities. Thus, with the acquisition of the BIAXTRONIC CO ITA is looking forward to undertake collaborative projects with national and international partners in the coming years. ITA plans to unveil the BIAXTRONIC CO on 21st January 2021 (save the date!) and cordially invites interested partners to attend the one-day industry event in Aachen.

This acquisition of the BIAXTRONIC CO is funded by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) and the state of North Rhine-Westphalia, project number INST 222/1264-1 FUGG. ITA extends its gratitude towards the DFG and the state of North Rhine-Westphalia for their financial support.