#Nonwovens / Technical Textiles

Tufropes to develop unique pentamerous technology based on Truetzschler Nonwovens’ and Voith’s CP equipment

Truetzschler Nonwovens and Voith are thrilled to be the technology partner for Tufropes’ (patent pending) unique nonwoven line based on pentamerous technology. The new installation relies heavily on Truetzschler/Voith core components for wet-laying, carding and hydroentangling. Proprietary refinements will allow Tufropes to produce any possible hydroentangled nonwoven material, including bio-degradable, natural fibre, eco-friendly high-performance nonwovens. Globally this would be a first industrial-scale pentamerous technology-based nonwoven project. Based in Gujarat, India, the line is expected to be commissioned next year.

India has a huge potential concerning hygiene-related nonwoven products. Wet and dry wipes lift hygienic standards in baby and body care. Since all these products are single-use items, the need for environmental-friendly products cannot be doubted.

Founded in 1992, Tufropes today is a leader in providing high quality and technologically superior rope and netting solutions. Known for its emphasis on quality and safety, Tufropes’ rope and netting solutions are used in a wide array of industries such as aquaculture, marine, safety, sports, shipping and defense.

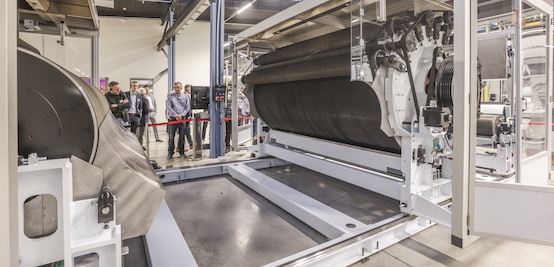

Targeting the nearly untapped market of locally made, disposable nonwoven products, Tufropes decided to embark on the journey of establishing a progressive and sustainable nonwoven production line with pentamerous technologies. Truetzschler/Voith’s carded/pulp (CP) technology combines a cost-effective, wet-laid pulp layer and a carded web layer from cellulosic fibres.

The management team at Tufropes opted for Truetzschler Nonwovens and Voith for good reason to supply machinery and be the technology partners in this new project.

“The team of Truetzschler and Voith stands out due to extensive experience with the wet-laid/hydroentangled d nonwoven technology. Several wet-laying/spunlacing plants and their CP line at a European customer is running at full capacity. Besides profound knowledge, expertise and running solutions, the local set-up of both companies in India convinced us. We wanted to invest in a unique and progressive technology and we are pleased to have found the best partners in Truetzschler and Voith to realise our first step into a new business field.”, says Tufropes’ Madhav Goel, (Promoter/Director).

Tufropes new production will deliver fully functional, affordable and 100% bio-degradable nonwovens. “A special advantage of our CP nonwovens technology is the very consistent distribution of stock suspension for highly flat profiles,” explains Oliver Crasser, Sales Manager Inclined Wire Solutions at Voith Paper. “The NCT high-speed card delivers a carded web into the manufacturing process. It offers additional flexibility in web forming and end products.”, adds Christian Maennich, Area Sales Manager at Truetzschler Nonwovens. A.T.E's Product Head for Nonwovens, Rupali Chitnis, closely works together with Truetzschler Nonwovens. She is excited: “Truetzschler and Voith implement a customer-oriented, tailor-made solution that guarantees an efficient and sustainable nonwoven manufacturing process. This project will equip Tufropes to manufacture superior quality, eco-friendly nonwoven products for the mass market. A perfect solution for India.”